In 1991, a Japanese physicist called Sumio Iijima applied an electric current across two graphite rods and changed the raw material supply chain for ever.

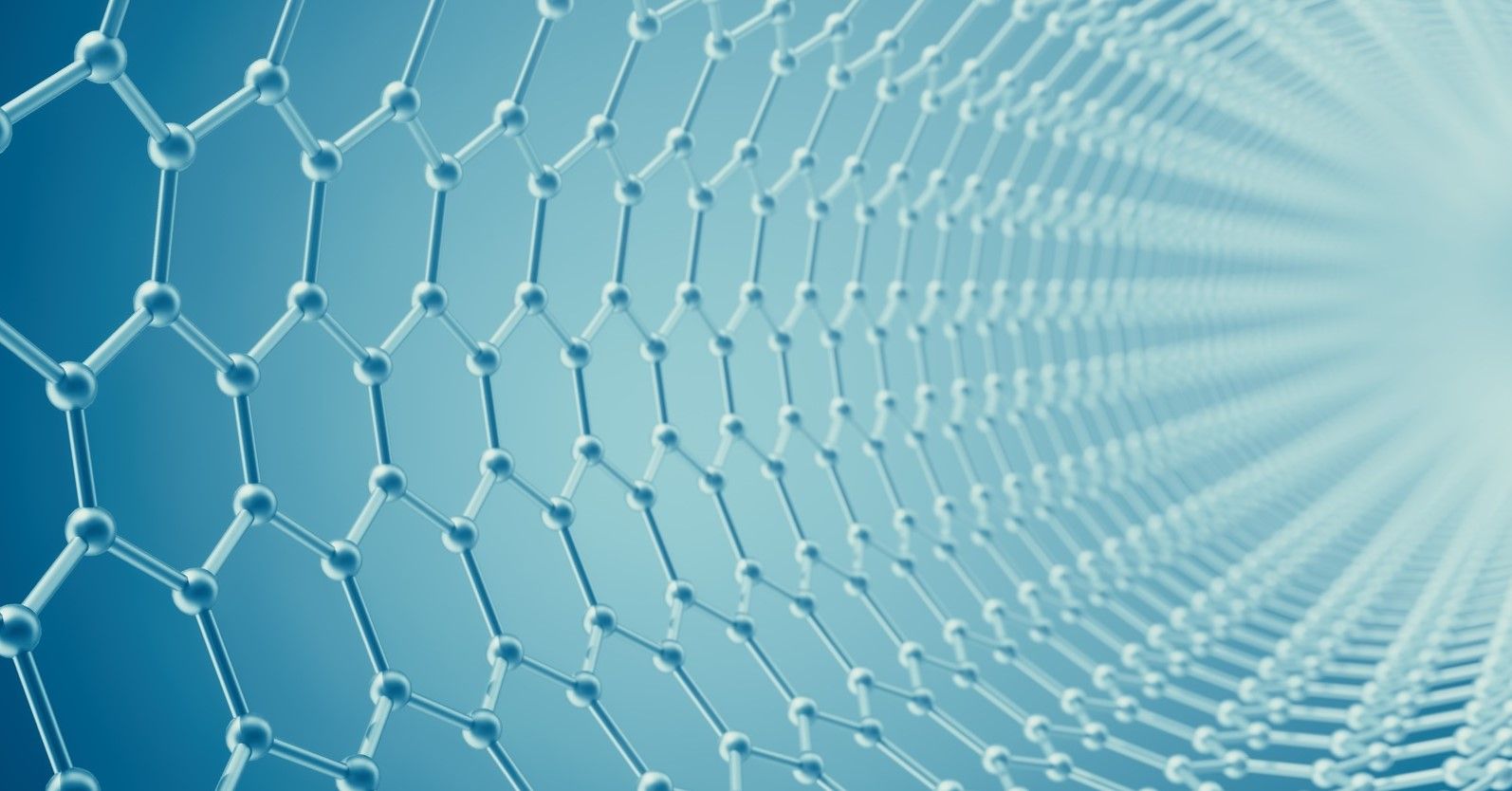

As the sparks jumped from one rod to the other, the tip of the anode rod vaporized into a cloud of gas. As the carbon-filled gas settled on the chamber walls, it left a thin layer of black soot. A dusty residue that on closer inspection contained carbon nanotubes – each measuring only a few nanometres (0.00001mm) in diameter.

Experiments on this and other nanomaterials showed that they had extraordinary properties. Carbon nanotubes are formed from a hexagonal lattice of carbon that is one of the most electrically conductive materials known to man. They also possess some of the strongest tensile strengths - about 100 time stronger than steel - and yet remain incredibly light.

These are all properties which make nanomaterials practical and versatile as a raw material.

For example, combining the low-weight, excellent electrical conductivity, and superb strength of nanotubes means that they could be used to replace aluminium in high-voltage power cables.

One of the best conductors of electricity is copper, however it is heavy and expensive, so most of the conducting cores of power cables are made of aluminium because it is strong and relatively light weight. However, considerable power is lost as the electricity is passed across the national power grid.

Electricity travels along individual nanotubes very easily, and the material’s low-weight and high-strength mean that fewer pylons would be needed, and less power would be lost on the journey from the power station to the consumer.

As yet, researchers have been unable to synthesize sufficiently long nanotubes for the switch to be made, but each year they are getting closer.

Material researchers have also found a whole array of other materials that can be formed at the nanoscale. Materials that are excellent at conducting light, make superb magnets, can be either excellent insulators or thermally conductive, and most significantly, nanomaterials that can be mixed in with other materials, passing on these properties to industrial ingredients.

The three decades since Iijima discovery has revolutionised the supply of raw materials, with nanotechnology now applied to hundreds of thousands of products in countless industries. Today, agriculture, pharmaceuticals, coatings, construction, electronics, advanced composites, animal husbandry, computing, ceramics, polymers, glass, and the metallurgy industries all use nanotechnology.

The challenge that remains is converting newly discovered nanotechnologies into specific industrial applications and products.

Understanding the issues of raw material supply and manufacturing, the nanotechnology experts at NANO CHEMI GROUP have created a wide range of products which can be combined with conventional raw materials during the manufacturing process to provide unique selling points.

These include:

· NANO AF EPO-58: a concentrate mixture of bisphenol A/F epoxy resin and 0,5 wt.% carbon nanomaterials which provides electrical conductivity, electromagnetic properties, thermal conductivity, abrasion resistance, chemical resistance, and mechanical strength.

· NANO AP PCG-23: a modified PC granulate (polycarbonate) that contains 0,12 - 0,25 wt.% of carbon nanomaterials which provides electrical conductivity, electromagnetic properties, thermal conductivity, and ultra-Violet protection.

· NANO AC PES-17: a polyester resin (isophthalic resin) based concentrate containing 0,2 - 0,5 wt.% of carbon nanomaterials which provides electrical conductivity, electromagnetic properties, thermal conductivity, abrasion resistance, chemical resistance, and mechanical strength.

· NANO AC FF-70: a concentrate consisting of a mixture of phenol formaldehyde resin and 0,05 – 4 wt.% of carbon nanomaterials depending on the formulation.

Concentrate NANO AC FF-70 is widely used in polymers to permanently increase antistatic, dissipative or electroconductive surface and volume properties, as well as boosting thermal conductivity, chemical resistance, and mechanical properties.

· NANO AF MMA-48: a methyl methacrylate resin-based concentrate containing 0,4 wt.% of carbon nanomaterials which provides electrical conductivity, electromagnetic properties, thermal conductivity, abrasion resistance, chemical resistance, and mechanical strength.

View the full list of products here.

Like the nanotechnology and manufacturing industries as a whole, innovation at NANO CHEMI GROUP is ongoing.

For this reason, the company has teamed up with nanomaterial scientists from Hamburg Technical University, The Sumy State University, The Leibniz Institute for Polymer Research in Dresden, The Ukrainian Academy of Science, Heyrovsky University, and the Nanotechnology Centre at the Technical University of Ostrava – VSB-TUO to create a ‘design-to-order’ nanotechnology service for manufacturers.

It is a service which allows manufacturers to order nanotechnologies that provide the added mechanical strength, chemical resistance, antimicrobial, electroconductivity, electromagnetism, and UV protection properties that their customers are looking for. Nanomaterials can even be designed to replace more expensive, conventional raw materials, thus lowering costs.

Nanotechnology is rarely a ‘one size, fits all’ solution.

Instead, through careful manipulation of nanotechnologies, raw material experts are able to solve specific challenges in the manufacturing sector. Providing a tailor-made route to better products that can save money and increase product sales.

A revolution in raw material supply made possible thanks to Sumio Iijima and his discovery of carbon nanotubes.

To learn more visit: NANO CHEMI GROUP

Photo credit: Bence Szemerey from Pexels, Freepik,