Some things naturally go together well – strawberries and cream, bread and butter, cheese and wine. But beyond food, one of the latest combinations to come to market is the addition of nanomaterials to polycarbonate granulate.

Polycarbonate is already known as a versatile material and is widely used in the manufacture of countless items, such as display cases, machinery guards, picture framing, medical devices, automotive components, retail poster displays, in LEDs, boat windows, helicopter canopy windows, warehouse lighting, and even bullet resistant lamination.

It has excellent impact strength and, as a thermoplastic, it is easier to recycle than other polymers.

Polycarbonate can even be used with some 3D printers using the FDM process. A method which requires the polymer to be used in filament form with a process where the 3D printer heats and deposits the PC into a specific 3D shape.

However, adding carbon nanomaterials can make polycarbonate even more impressive by boosting its inherent UV protection, increasing impact strength to even higher levels, and adding antistatic properties.

Nanotechnology can even restrict one of PC’s key disadvantages – poor scratch resistance. This can lower manufacturing costs for a PC product, as the increased scratch resistance from the inclusion of nanomaterials may mean that additional coatings from other materials are not needed.

This can be highly beneficial given the high demand for PC products that are both transparent and scratch free, such as security camera domes, protective glasses, and PPE face shields which limit the spread of viruses.

Another significant advantage of applying nanomaterials to PC is the improved electrical conductivity which can prevent electrostatic discharge (ESD).

In today’s highly digital world, polycarbonate is being increasingly used in places which require protection from the build up of static electricity. For example, polycarbonate sheeting is often used in the construction of industrial control screens, anti-vandal touch screens (such as public information displays, ATMs, etc.), control panels on agricultural equipment, and LCD display panels for large portable generators.

A sudden electrical discharge can seriously damage or destroy any of these expensive pieces of equipment. This can require extensive repairs, lost production time, and the possible deletion of priceless electronically stored data.

All of which can be avoided with the smart application of nanotechnology.

There are evidently numerous ways to give polycarbonate properties that will truly make it a product of the 21st century; a more versatile product which performs better and is easier to sell. However, applying nanotechnology to PC requires detailed knowledge of both nanomaterials and polymers.

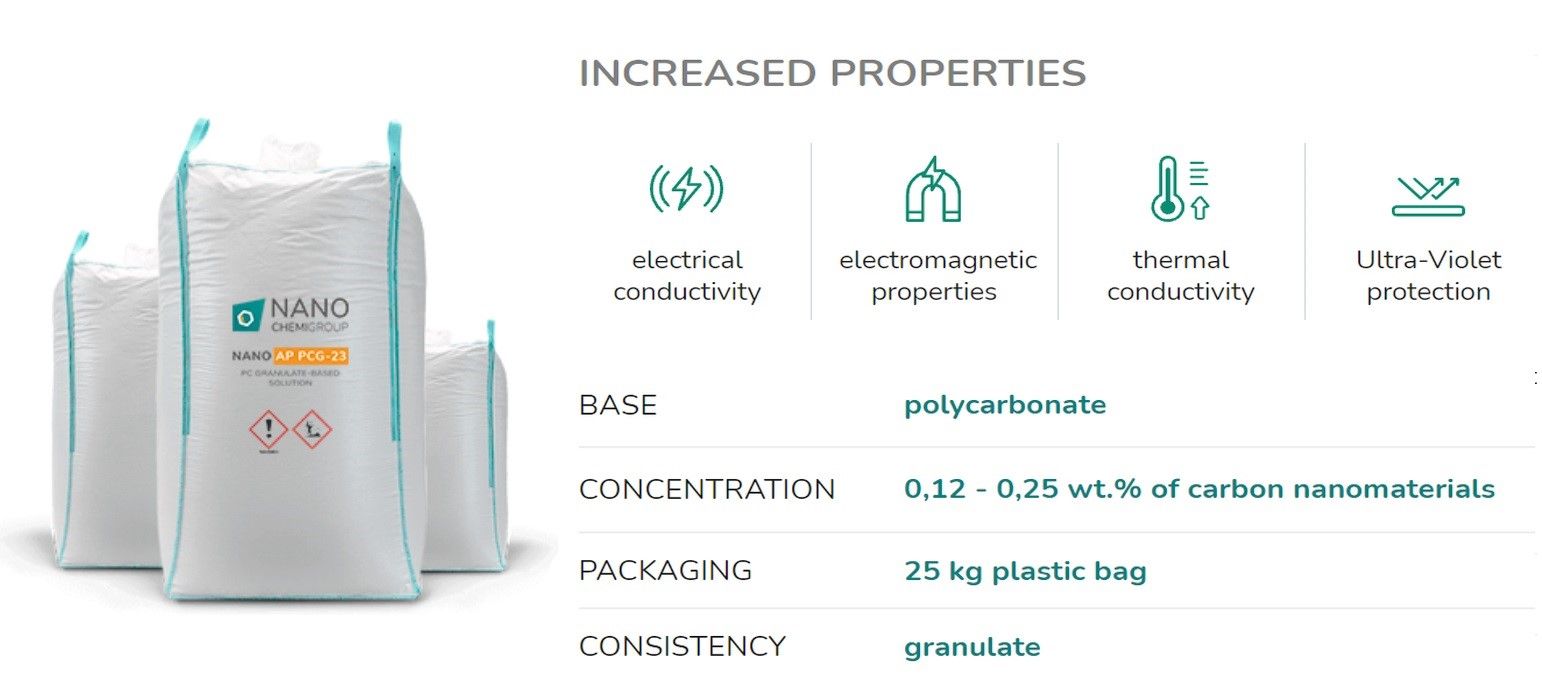

NANO CHEMI GROUP are experts at combining the best that nanotechnology has to offer in polymer materials. Their product, NANO AP PCG-23, is a modified PC granulate that contains 0,12 - 0,25 wt.% of carbon nanomaterials. It is a polycarbonate which is widely used to permanently increase antistatic, dissipative, or electroconductive, as well as mechanical properties.

NANO CHEMI GROUP (who support this webpage) is a Prague-based supplier of nanotechnology for use in manufacturing.

By cooperating with material research teams across Europe, NANO CHEMI GROUP has been able to develop cost-effective processes for the modification of polymers with carbon nanomaterials. They already possess two technologies with patents pending which are capable of enhancing products with new properties.

Additionally, polymer manufacturers are able to request ‘design-to-order’ technologies which can give their products properties such as electromagnetism, scratch resistance, impact strength, electroconductivity, chemical resistance, thermal conductivity, and more.

If you are interested in giving your polymer products a sales boost or unique selling point, then contact NANO CHEMI GROUP.

Photo credit: Cleyder Duque from Pexels, Testalize.me on Unsplash, Filip Bunkens, NANO CHEMI GROUP, & Дмитрий Хрусталев-Григорьев