Physicists have been debating the power of nanotechnology since the late 1950’s and chemists have been creating them since the early 1990’s, but only now are nanomaterials even beginning to show any of their true potential.

In fact, the application of nanomaterials is no longer a small, technological backwater, but a consolidated sector of manufacturing. Today, whatever your raw material problem is, there is a chance that nanotechnology can solve it.

Nanomaterials can be found in thousands and thousands of products. This is because they can add exceptional properties to make materials stronger (or not), more flexible (or not), magnetic (or not), electrically conductive (or not), thermally conductive (or not), and more elastic (or not).

They make sun creams more UV resistant, they stop paint from cracking and fading, they make coatings scratch resistant, or give materials increased protection against extreme temperatures or harsh chemical environments.

One material that is taking full advantage of what nanotechnology has to offer is plastic.

Plastic is already used in so many, many objects. It makes cutlery, windows, aeroplanes, furniture, ships, clothing, safety screens, helmets, electronic devices and household goods, brushes, cleaning cloths, picture frames, household plants, insulating material, sound-proofing materials, dishware, car parts, pipes, and billions of pieces of packaging, to name but a few.

However, nanotechnology is now making plastic even more practical and versatile. It is used to make aeroplanes and ships more fuel efficient and to make helmets give better protection. It can limit electrostatic discharge in containers and so make transporting flammable goods safer. It can be applied to gas and fuel pipes (either in buildings or vehicles) to reduce the chance of an explosion, as well as helping insulating and sound proofing materials both perform better.

Cutlery, dishware, and packaging with nanomaterials can all be given anti-microbial properties to limit the spread of viruses and bacteria. The same technology can also be applied to textiles to make better face masks and more hygienic clothing for hospital and care workers.

Electrical devices which can be destroyed by static electricity can be better protected from sudden discharges, while electronic data can be more safely stored. Nanomaterials can also provide an added defence against scratches, cracking, and abrasion in windows, furniture, door handles, stair rails, polymer flooring systems, and other high contact surfaces.

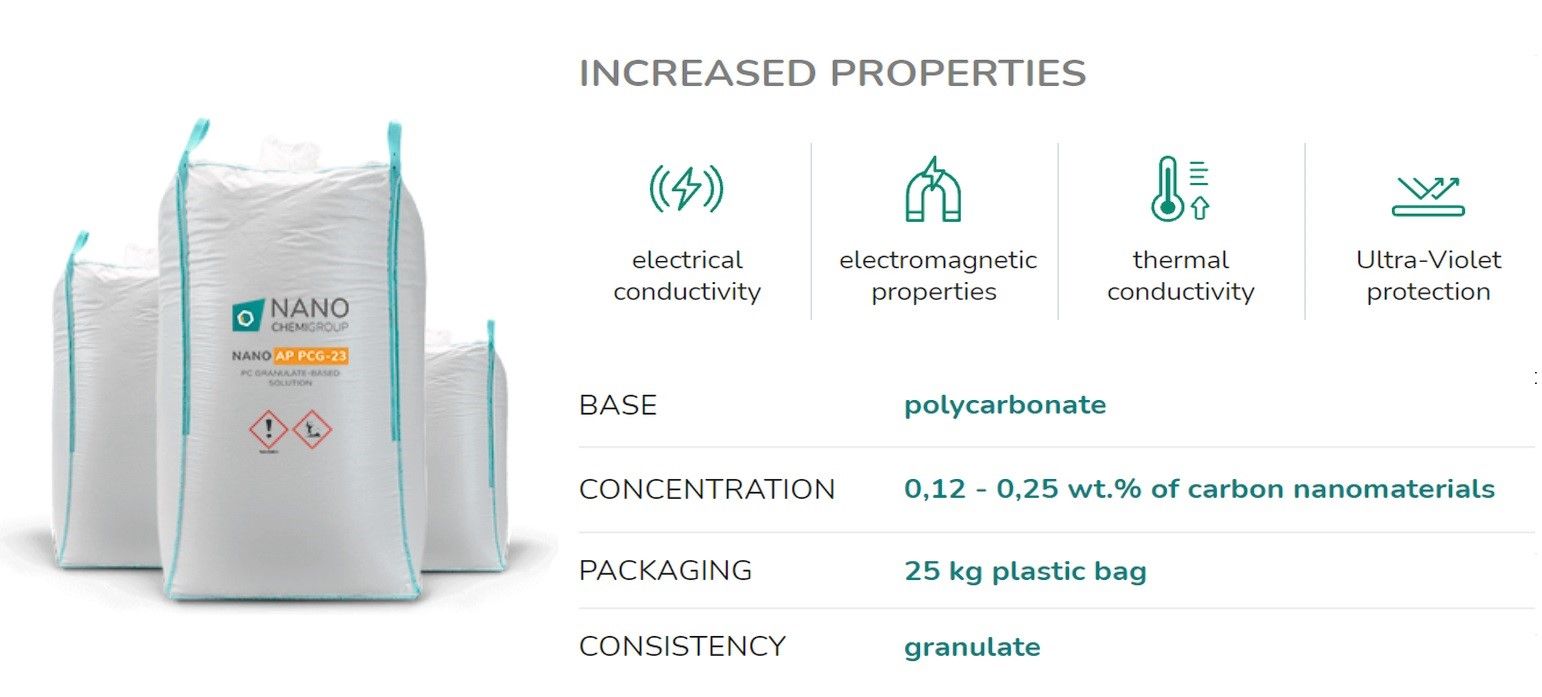

One example of nanotechnology successfully being applied to everyday materials is the PC granulate-based product NANO AP PCG-23 which can be used in the manufacture of different compounds to give ESD properties.

Manufactured with rotational moulding technology, the product’s carbon nanotubes add conductivity to plastics used in contact or proximity to flammable or explosive liquids and powders.

Supplied by NANO CHEMI GROUP (who support this website), NANO AP PCG-23 provides:

· Permanent and stable anti-static properties without ‘hot spots’

· Coloured tank: surface resistivity of 107 Ω/sq

· Black tank: surface resistivity of 106 Ω/sq

· Increased mechanical strength

Other nanotechnology-devised fillers can be applied to a broad range of products (including PP, PE, PA6, PET, PET-G, and others) to adjust the surface electrical resistance, this includes use in ESD, EMI/RFI, antistatic, and conductive polymers such as PP and PE. The process is also compatible with recycled plastic feedstock.

“Nanostructure technology allows 100% modification of secondary raw materials, both in order to maintain the conventional properties of materials at the required level (for example, impact strength) and in order to obtain new material properties (for example, obtaining thermally or electrically conductive plastics),” explains Lev Lyapeikov, NANO CHEMI GROUP’s product development manager. “It is a process which can modify either the entire volume of a material or only its surface for a more efficient use of nanoparticles.”

The advantage of using nanoscale sized particles (nanofillers) in polymers is because they have such an extremely high specific surface area, typically ranging from 800 to 1,600 m2 per gram of filler.

With such a high surface area, the chemical impact of the nanomaterials is highly efficient, meaning that only an incredibly low loading rate (starting at 0.025% or less) is required. As a result, bulk materials can maintain all of their original properties, while still gaining the desired mechanical, conductive, or electromagnetic qualities.

For these reasons it is clear to say that nanotechnology is not a niche solution. Instead, it is a versatile approach to improving conventional properties as well as providing added qualities and unique selling points in bulk materials.

To learn more about the PC granulate-based product NANO AP PCG-23 and how it can improve performance and save money visit NANO CHEMI GROUP.

Photo credit: Freepik, NANO CHEMI GROUP, Michael Schwarzenberger, vedat zorluer from Pixabay, NANO CHEMI GROUP, & Pashminu Mansukhani