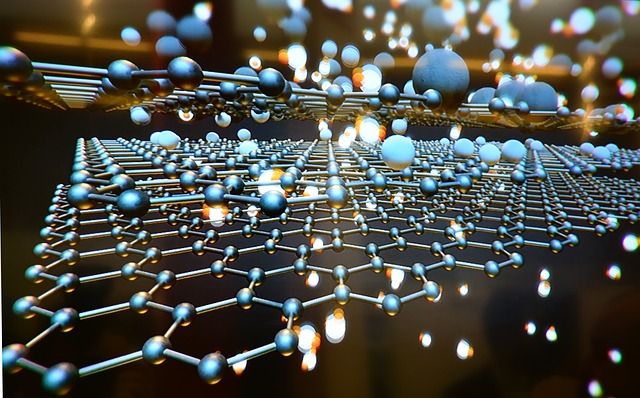

Nanomaterials are truly extraordinary.

For example, laboratory testing using atomic force microscopes on graphene (a nanomaterial sheet of carbon only one atom thick) has shown it to have a Young's modulus of 0.5 Terra pascals and an ultimate tensile strength of 130 gigapascals. This tells us that it is a material so strong, that a perfect sheet of graphene could make a hammock so thin that it would be invisible to the naked eye, yet would be strong enough to support the weight of a cat.

The problem is that the perfect sheet of graphene is not yet within the capabilities of modern technology.

But this does not mean that nanotechnology is only theoretical. Nor does it mean that nanomaterials are confined to the laboratory.

Instead, there are countless real-life applications for nanomaterials, with an almost endless array of future possibilities.

Take for example, an ordinary product such as plastic. It is already used to make hundreds of thousands of different items and yet, nanotechnology could make the plastic industry even more versatile, as well as greener.

Nanomaterials Make Plastics Stronger

The exceptional strength of nanomaterials means that they can be combined with polymers to make a plastic that is stronger than steel.

This can be achieved without the plastic becoming excessively brittle and while still maintaining the plastic’s high durability and low toxicity. Applications for plastic/nanomaterial composites are widespread and are used to make:

· Stronger, leak-resistant fuel tanks.

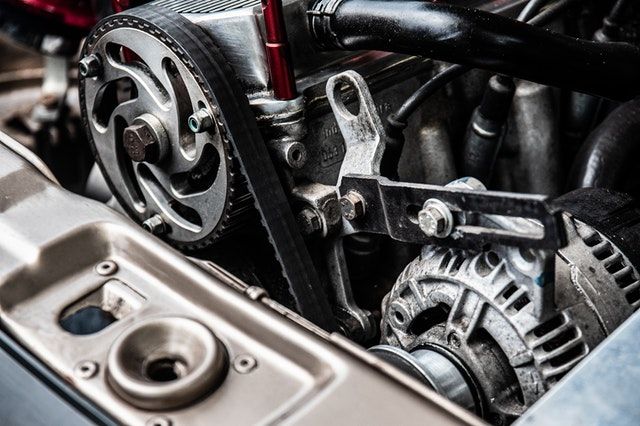

· Lighter, more fuel-efficient aircraft and car parts.

· Air-tight plastic containers that keep food fresh for longer.

· Stronger wind turbine blades.

· Longer-lasting medical implants.

· Improved sports equipment.

Nanomaterials Make Plastics More Versatile

Beyond the uses for plastics made stronger with nanotechnology, are the varied other properties that can be applied. These include:

· Added electrical conductivity. This application allows for polymers to be used to prevent the build up of static electricity. This can be an invaluable addition, especially in places where expensive electrical equipment is used or stored. For example, warehouses storing electrical components, shelves and casing for computer servers, technical work benches for sensitive electronics, flooring systems using resins for hospitals and technical office spaces, etc.

Electrical conductivity is also useful in products used with flammable and/or explosive materials, such as fuel lines, containers for petrol, fertilizers, and other combustible materials, etc.

· Anti-microbial properties. Polymers with nanomaterials can be designed to kill pathogens on contact. They can then be used to prevent the spread of infection on high contact surfaces such as door handles and stair rails. They can also be applied to medical devices or food handling and storage equipment.

· Thermal conductivity. Polymers with boosted thermal conductivity can be used in various heat-sink applications, such as electronics, housings for moving parts where heat friction is an issue, or in automotive parts.

· Chemical resistance. Polymers with added chemical resistance are useful for making containers for storing harsh chemicals, or for products frequently used in extreme environments.

· Electro-magnetic properties. Polymers with these properties can be used in the manufacture of electro-magnetic induction (EMI) shielding enclosures, can be applied to materials used to absorb EM, as well as being a practical property for radio frequency (RF) components.

Nanomaterials Make Plastics Greener

Nanotechnologies have already been shown to improve the recyclability of some plastics, while the ability to make plastics stronger, means that less is needed to perform the same task.

Additionally, the increased use of nanomaterials in composites is likely to be better for the environment, as super strong and versatile polymers can replace other materials. For example, the production of steel requires higher temperatures and larger amounts of energy than producing plastic.

Furthermore, as they are lighter, plastic components are also more fuel efficient than their metal counterparts.

Nanomaterials Can be Tailor-Made for Plastics

Beyond all the applications of nanomaterials in plastic already mentioned, nanotechnologies can also be designed-to-order.

Polymer manufacturers need only request the additional properties they would like their plastics to have and leave the technology to the experts. In this way, manufacturers can improve their products, increase their sales, and expand into new markets.

One firm that specialises in this novel approach to raw material design is NANO CHEMI GROUP.

Following a short consultation with nanotechnology process designers, clients of NANO CHEMI GROUP (who support this website) are able to solve specific manufacturing issues, improve end-products, save input costs, reduce product application times, lower energy bills, and/or provide unique selling points.

It is a tailor-made designing of raw materials which enables the manufacturing sector to bridge the gap between nanotechnology and industrial production.

If you would like to learn more about nanotechnology’s impact on manufacturing then visit: NANO CHEMI GROUP or call +420 233 371 850

Photo credit: Rupert Kittinger-Sereinig from Pixabay, Jonas Morgner on Unsplash, Lalit Kumar, Dean Simone from Pixabay, OpenClipart-Vectors, seagul, & Hebert Santos