Nanotechnology is a crucial topic for chemists, physicists, businessmen, investors, computer scientists, and material researchers. But what does it mean for those involved in the supply and procurement of industrial materials?

How is nanotechnology improving products and materials in the real world?

To answer this, take a look at four clever nanotechnologies and how they are simply making products better.

1. Plastic Given New Properties with Carbon Nanomaterials

In the multi-purpose field of plastics, nanotechnology can provide a variety of benefits for enhancing the original properties of a material or for providing completely new qualities.

For example, by adding nanoparticles (such as silver, copper, zinc, or even carbon) to a plastic, it can be made stronger or weaker, or more rigid or more flexible. Its melting point can be altered, flammability reduced, resistance to UV radiation can be added, or it can be given improved or reduced electrical or thermal conductivity.

Today, nanotechnology is easier to apply than ever before, as cutting-edge nanomaterials can be applied either throughout the whole volume of a polymer or only at its surface.

With plastic already having an incredible number of uses, the ability to further boost its properties, add new qualities, remove unwanted traits, or provide unique selling points is certain to increase its versatility even further.

In so many way, nanotechnology is having a clear impact on polymer manufacturing.

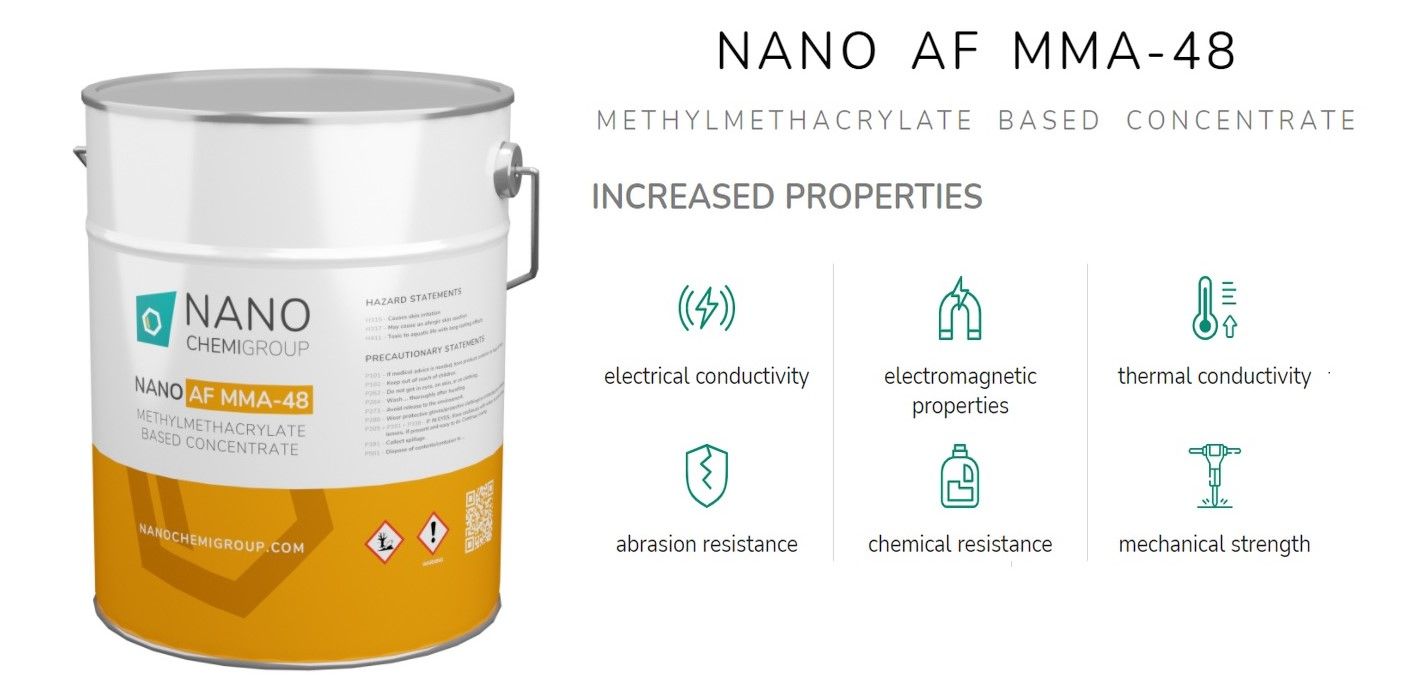

2. Epoxy Resin and MMA Flooring Systems with Electro-Static Discharge

Flooring systems in warehouses, factories, hospitals, and other high use areas are often plagued by electro-static discharge.

As the floor is driven or walked across, friction between footwear and wheels causes a build up of static electricity. When this electricity is suddenly discharged, it can damage expensive machinery, destroy sensitive electronics, erase electronically stored data, start a fire, and (if combustible materials are being stored) even cause an explosion.

Working in cooperation with Hamburg University of Technology (TUHH) and the Academies of Science in both Prague and Kiev, nanotechnology specialists at NANO CHEMI GROUP have created a nanoadditive suitable for use in the manufacture of ESD flooring.

Called NANO AF MMA-48, the product is a methyl methacrylate resin-based concentrate containing 0,4 wt.% of carbon nanomaterials.

It is a nanoadditive that has been proven to dissipate electrical static to a standard suitable for use in ESD and ASD floorings.

Specifically, tests conducted by a Wolfgang Warmbier, Surface Resistance Meter SRM110 on MMA samples produced with NANO AF MMA-48 were found to have a surface resistivity of 106 ohm/sq.

3. Nanotechnology gives Coatings Improved Chemical Resistance

The protective ability of a paint or varnish is crucial to its sales success.

However, most coatings do not work in extreme environments. They lack scratch resistance, fade quickly, or crack, especially in places exposed to heat or toxic chemicals.

For this reason, nanomaterial specialists have developed NANO CR Coating; a chemically resistant paint for use in aggressive environments.

Made by the Prague-based company NANO CHEMI GROUP (who sponsor this webpage), NANO CR Coating is an epoxy-based paint designed specifically for use on trucks, tanks, and equipment for storing, transporting, or using high concentrations of industrial materials, such as salts or acids.

A simple but effective use of nanotechnology that can save money by extending the lifespan of expensive machinery and equipment.

4. Nanotechnology Applied to Polycarbonate Sheeting for Anti-Microbial Properties

Makers of plastic ‘sneeze screens’ have seen a tremendous growth in the market as the pandemic has required the installation of clear, protective barriers in almost every shop, restaurant, and public service area.

Polycarbonate sheeting is the most common material used for these screens due to its strength, transparency, flexibility, stability, and low cost.

Unfortunately, the nature of a ‘sneeze screen’ or any high-contact counter surface means that they can quickly collect pathogens and become a breeding zone for bacteria and viruses.

Nanotechnology processes to incorporate nano silver solutions into polycarbonate products are now able to solve this issue.

“We now patent technologies which allow us to modify the top layer of polycarbonate plates with nano-structured polycarbonate with high efficiency against pathogens,” explains Mr Lev Lyapeikov, the Product Development Manager at NANO CHEMI GROUP. “Specifically, this process can provide nanomaterials with active anti-microbial properties.”

“We are also conducting more tests on modified polycarbonate materials with our nanomaterial product NANO AB PA6 to achieve even better antibacterial properties,” adds Alexandra Chepak, the company’s Market Development Manager

While the market for polycarbonate screens may not be huge, other nanotechnologies are being devised that can apply anti-microbial nanomaterials to other polymers and metals. This will allow for their application on door handles, desks and counters, touch screens, and even medical appliances.

It is an application of nanotechnology that is key, not only limiting coronaviruses, but also in killing common bacteria, as well as hospital superbugs and other infections.

One of the key advantages of nanomaterials is that their incredibly low weighting (typically 0.5% wt. volume or less) means that they do not negatively impact the desired properties of a bulk product. Consequently, a coating can still maintain a desired colour, a flooring system remains durable and easy to pour, and a plastic is still as strong, soft, rigid, or as flexible as needed.

With these nanotechnologies, and others like it, it is possible to improve products in a whole range of ways.

To see other nanotechnologies that can provide further properties, take a look at NANO CHEMI GROUP’s product range.

Alternatively, NANO CHEMI GROUP provides a ‘design-to-order’ service which allows for manufacturers to have nanotechnologies ‘tailor-made’. Simply speak to a nanomaterial specialist about the properties required in any specific material, and our team will find a nanotechnology to suit.

For further information, visit NANO CHEMI GROUP, write to info@nanochemigroup.cz or contact +420 233 371 850.

Photo credit: feiern1 from Pixabay, Silas Camargo Silão, Marlon Falcon Hernandez, hangela, & Freepik