The COVID pandemic has made everyone pay more attention on staying healthy.

One small, but significant, step towards this goal part is the use of plastic sheeting as a protective barrier between customers and the shop assistants working at the counter. These so-called ‘sneeze screens’ provide an effective shield to lower the risk of infection and are widely used in shopping centres, government buildings, at sales points, information booths, hospitals, and other public spaces.

Polycarbonate sheeting is the most common material used for these screens due to its strength, transparency, flexibility, stability, and low cost.

Unfortunately, the nature of a ‘sneeze screen’ or any high-contact counter surface means that they can quickly collect pathogens and become a breeding zone for bacteria and viruses.

A key study published in the Journal of Clinical Microbiology found that on the polymer surfaces and screens tested, staphylococcus aureus (MRSA) and vancomycin-resistant enterococci (VRE) “… survived for at least 1 day, and some survived for more than 90 days on the various materials.”

Restricting the spread of infection requires repeated cleaning with an anti-bacterial spray or other chemical, which costs both time and money.

A new alternative to constant cleaning is the application of nanotechnology which can be used to kill pathogens that come into contact with polycarbonate materials.

Making Polycarbonate Materials Anti-Microbial

An effective anti-microbial polycarbonate screen requires the following attributes:

· Safe to use

· Long-term effectivity against pathogens

· Wide range of anti-microbial activity

· High stability

Leading the way in the application of nanomaterials in polycarbonate materials is the industrial raw material supplier NANO CHEMI GROUP.

Based in Prague, the company (which sponsors this website) has developed numerous nanotechnology processes to incorporate nano silver solutions into polycarbonate polymer products. However, what makes NANO CHEMI GROUP’s nanotechnology polycarbonate special is the efficient use of the nanomaterials employed.

“We now patent technologies which allow us to modify the top layer of polycarbonate plates with nano-structured polycarbonate with high efficiency against pathogens,” explains Mr Lev Lyapeikov, the company’s Product Development Manager.

Significantly for polymer manufacturers, the new nanotechnology is more cost-effective than previous approaches.

“As the process involves only a surface treatment of the polymer granules with a layer of nanoparticles, without the need to melt all the material, this technology makes it possible to obtain high-quality dispersion and distribution of nanoparticles on the polymer surface, thus reducing the consumption of expensive nanomaterials and increasing the efficiency and functionality of nanomaterials in modified polymers,” notes Mr Lyapeikov. “Specifically, this process can provide nanomaterials with active anti-microbial properties.”

This means that polycarbonate sheeting can be made to kill pathogens on contact with very little additional expense. While analysis is ongoing to see if the process can be further improved.

“We are also conducting more tests on modified polycarbonate materials with our nanomaterial product NANO AB PA6 to achieve even better antibacterial properties,” says Alexandra Chepak, NANO CHEMI GROUP’s Market Development Manager.

It is an approach to plastic production that is finding growing demand in a multitude of markets, not least because of the ongoing pandemic.

As Timothy Kneale, an MIT chemical engineer with decades of experience in developing commercial polymer products, observed in a recent report in Plastics Today, “A balance of properties, including purity, clarity, sterilizability, and chemical resistance, is driving the use of [anti-microbial] polymers in applications ranging from diagnostic products and wearable insulin devices to primary drug packaging.”

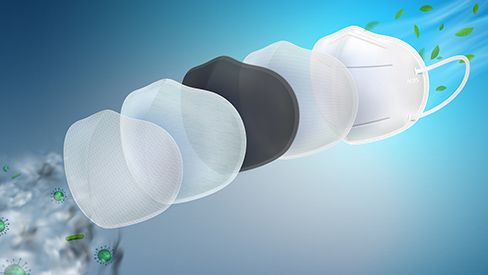

NANO CHEMI GROUP, for example, has seen significant interest in its nanomaterial technology to be applied to the polymers used in face masks and respirators.

While polycarbonates are more limited in their range of applications, the growth in the use of anti-microbial plastics in all areas is likely to further boost demand for any polymer product modified with nanomaterials.

A report conducted by consultants at Grandview Research, found that the anti-microbial plastics market is predicted to grow yearly by 8.2% from $25.5 billion in 2020 to $44.1 billion in 2027.

Furthermore, the development of other polymers to be given anti-microbial properties through the application of nanotechnology processes is also expected to be a growth market.

For example, polymers used to make simple hospital equipment are expected to be in much greater demand in the coming years. Recent research published in the journal Macromolecules finding that, “… catheter-associated infections account for more than 3 billion dollars annually in hospitals.”

Alternatively, polymers used to make bandages and dressings are prime targets for the application of anti-microbial properties in a wound care industry which the journal Acta Biomaterialia, reports as having a, “… global market of $20.4 billion.”

Clearly, even if the current pandemic subsides in the coming months, the need for anti-microbial properties in polymers such as polycarbonate will remain strong.

For a long time now, nanomaterial science has promised industrialists technological advances that will change our world. Today, specialists, such as the experts at NANO CHEMI GROUP, are providing solutions to everyday problems in the manufacturing sector.

Part of that includes providing polycarbonate sheeting with anti-microbial properties to keep us all safer.

Photo credit: NANO CHEMI GROUP, Edinaldo Maciel edy boy from Pixabay, Marlon Falcon Hernandez, & Direct Media from StockSnap