For many years, chemical engineers have been investigating the interaction between nanotechnology and polymers, finding numerous ways to improve substances through the addition of nanomaterials.

As engineering researchers from MIT and the University of Hong Kong note, “The excellent physical, mechanical, thermal and electrical properties of carbon nanotubes (CNTs) make them promising reinforcements for polymer materials.”

However, this research has typically gone no further than the laboratory door.

But now, nanotechnology specialists have cooperated with suppliers of industrial raw materials to provide commercially available nanomaterials that can improve epoxy resin flooring systems.

Why nanomaterials are a useful additive to polymer mixtures, and epoxy resins in particular.

Despite carbon nanotubes having a diameter measuring only 1/10,000th the width of a human hair, their robust architecture provides strength and crack resistance when added to polymers, including thermosetting materials such as epoxy resins.

Nanomaterials can also be modified so that they add thermal conductivity, chemical stability, and crucially electro conductivity. This makes them an ideal raw material for use in ESD (or ASD) flooring systems, all without losing the natural advantages that epoxy resin provides.

Many buildings use ESD (or ASD) flooring as the build-up of electrostatic may create a sudden discharge which can damage electrical equipment or cause an explosion or fire if flammable or combustible materials are being stored. With warehouses, hospitals, and publics spaces containing ever more delicate and expensive electrical devices (as well as digital data storage), demand for effective ESD flooring is growing.

The Strengths and Weaknesses of Epoxy Resins

Epoxy resins are exceptional materials with many outstanding characteristics. They have excellent mechanical strength and stiffness, as well as being durable, chemically stable, and corrosion resistant. They are also easy to apply, long-lasting, quick curing (with low shrinkage), and adhere well to a wide range of different materials.

These properties make them a practical and economically suitable solution for flooring systems, but not without their shortcomings.

As Prof. Mariaenrica Frigione, of the Department of Innovation Engineering at the University of Salento in Italy, explains, “Along with many withstanding properties, epoxy resins also display some weaknesses, such as very low values of toughness (they are brittle in nature, like other thermosetting polymers), low thermal/electrical conductivity, high coefficients of thermal expansion, and deficiencies that somehow restrict their use in some more demanding applications….”

Significantly, however, Prof. Frigione also notes that, “These properties can be on-demand modified, improved, or adjusted to address specific requirements with the addition of preformed nano-sized constituents, i.e., nanofillers.”

This is particularly useful when epoxy resin is desired for use in spaces which require a flooring system with electric static discharge (ESD).

Nanomaterials can be added to epoxy resin to provide the electro conductivity required in modern flooring systems.

An additional advantage of using nanomaterial concentrates in epoxy resin mixtures are the savings that can be made. As nanomaterials boost the strength, crack resistance, chemical stability, and electromagnetic properties of an epoxy resin flooring, they reduce the quantity of other raw materials required.

Consequently, manufacturers of epoxy resins are able to reduce their costs for raw materials, labour, and energy, as well as cut expenses on logistics and storage, all while producing a resin with a better conductive performance.

This means that an investment in a nanomaterial concentrate could actually save more money than it costs.

Using Nanotechnology to Improve Epoxy Resins

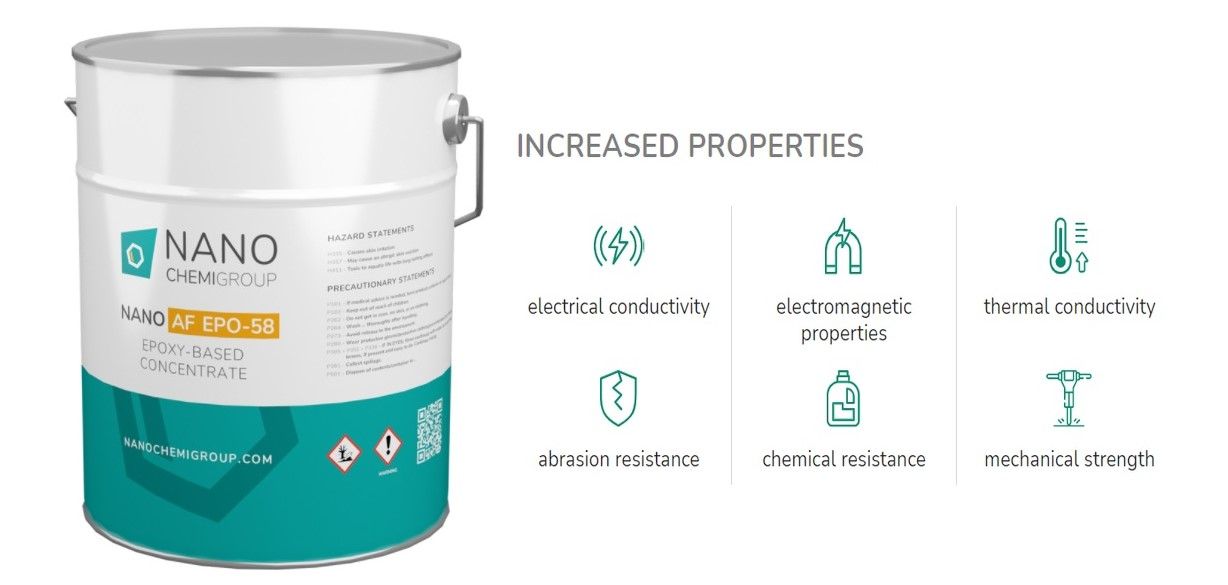

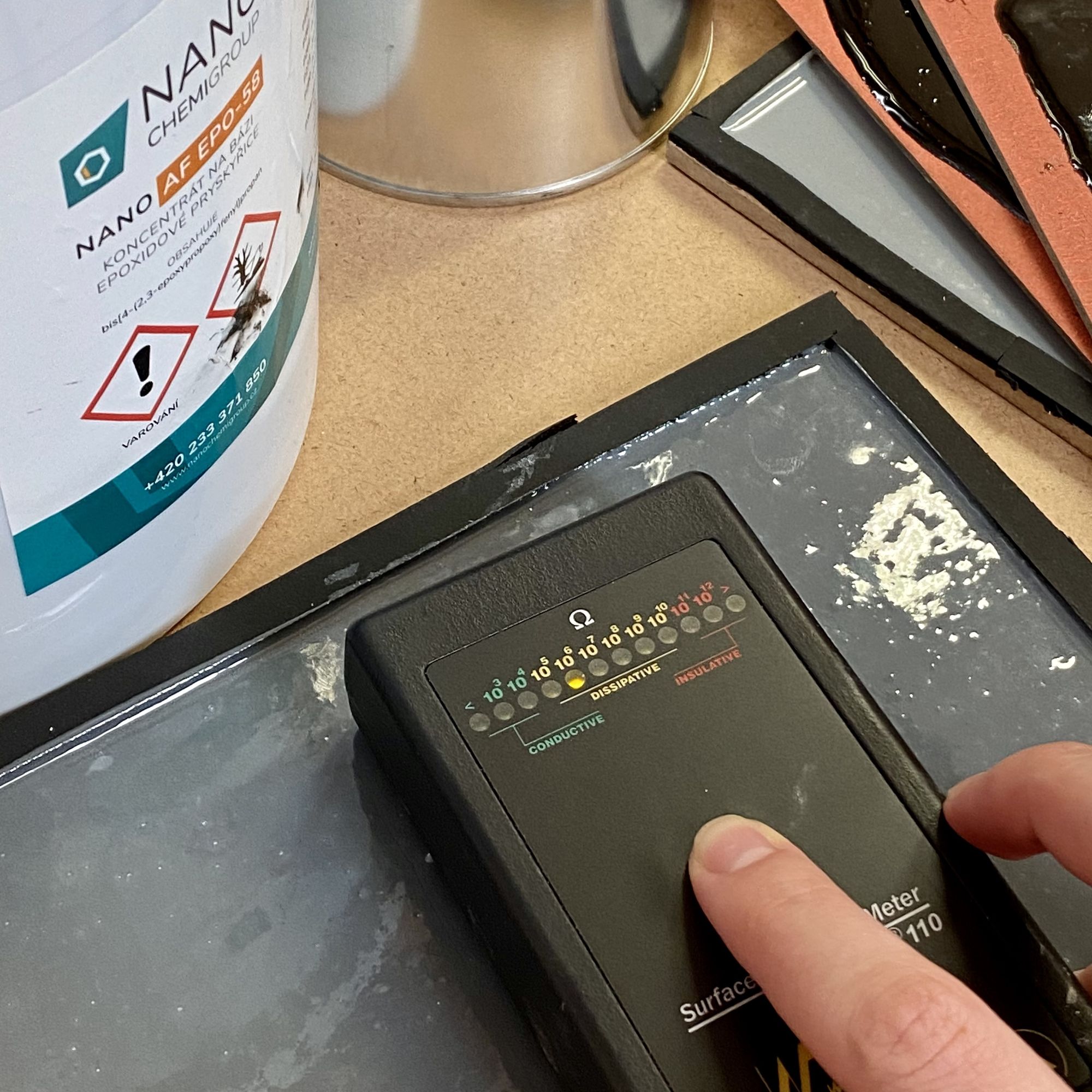

Taking the way that nanomaterials can modify epoxy resins alongside market demand for ESD flooring, the industrial raw material suppliers at NANO CHEMI GROUP have been in cooperation with nanomaterial researchers to produce a commercially available nanomaterial concentrate for improving epoxy resin flooring systems.

The result is NANO AF EPO-58- an industrial concentrate which consists of a mixture of bisphenol A/F epoxy resin and 0,5 wt.% carbon nanomaterials which is suitable for use in polymers to permanently increase antistatic, dissipative or electroconductive properties. NANO AF EPO-58 also improves mechanical properties such as crack resistance and strength.

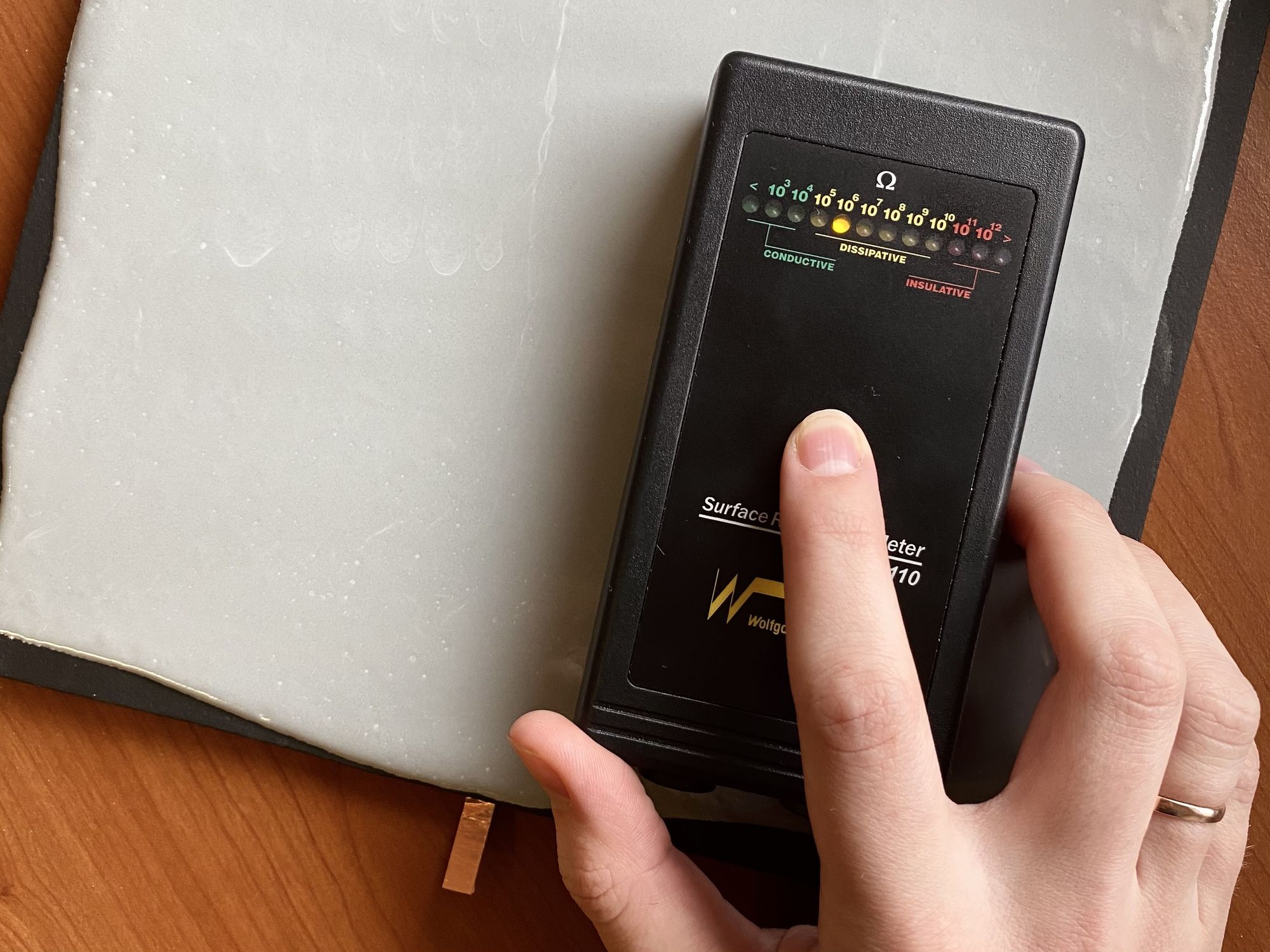

Evidence of AF EPO-58 as a Provider of Electroconductivity in Epoxy Resins

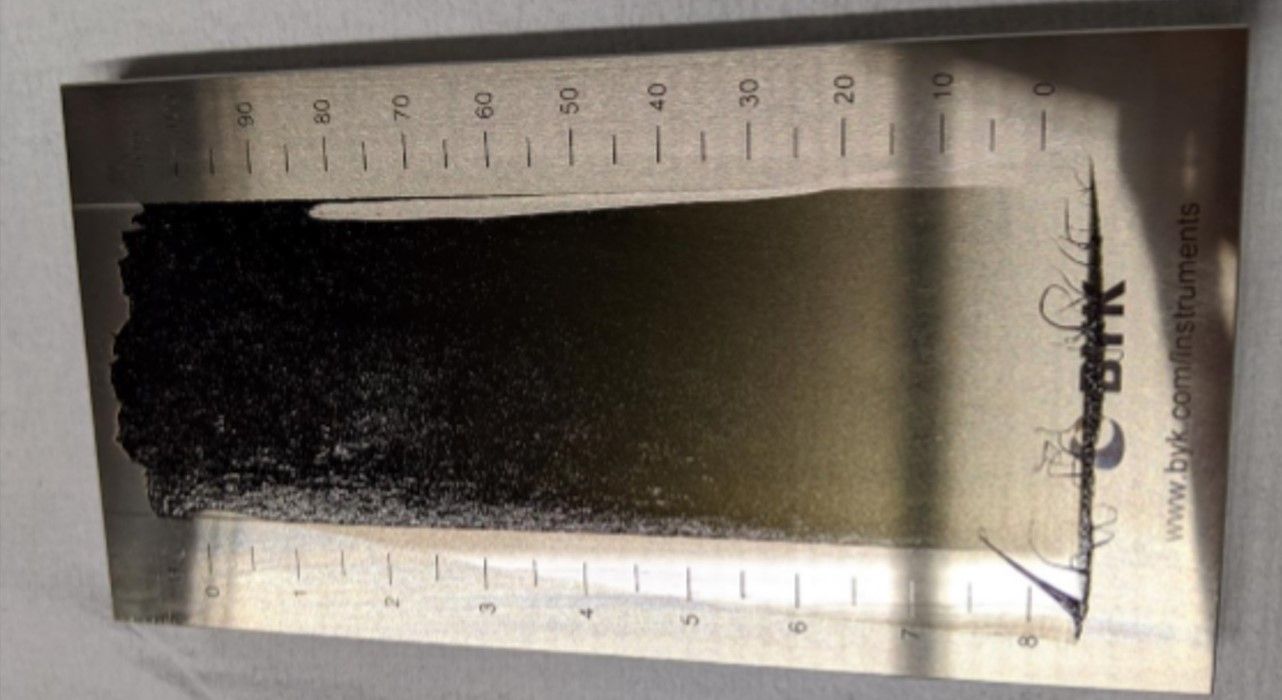

Specifically, NANO CHEMI GROUP’s cooperation with nanomaterial specialists at the Hamburg University of Technology (TUHH) included dispersing a masterbatch of epoxy resin with single-walled carbon nanotubes (SWCNT) to a low dilution of only 0.05 wt.% SWCNT.

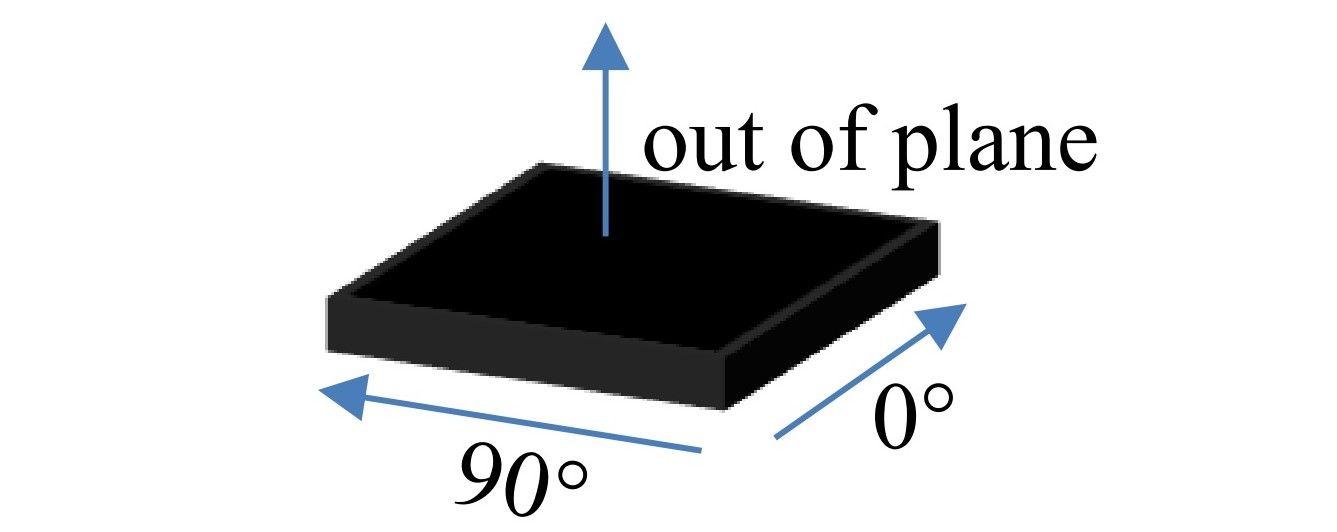

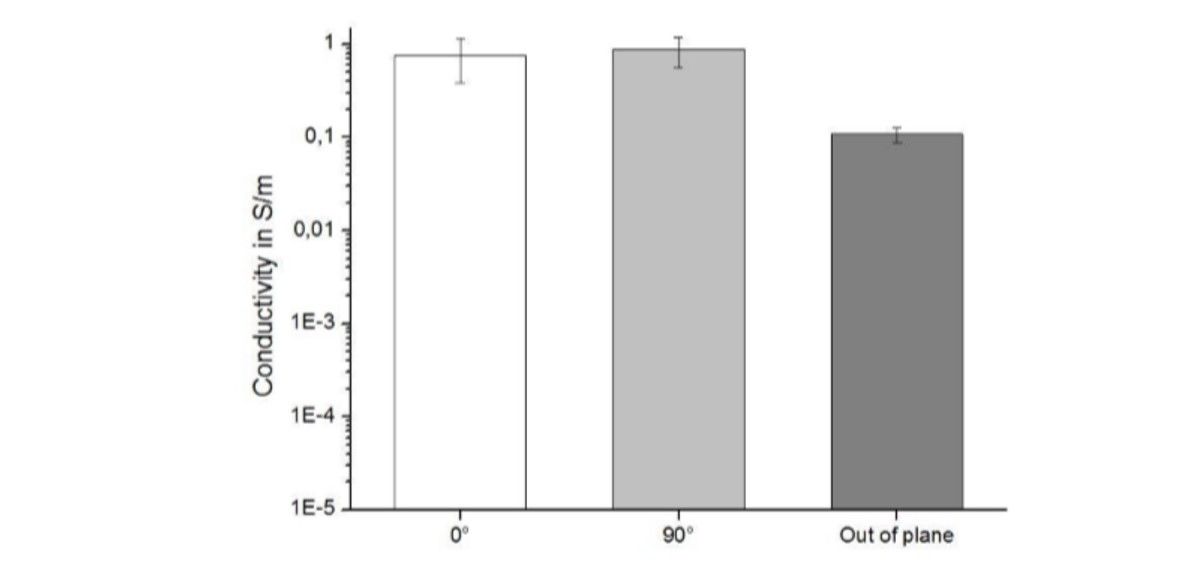

The conductivity of the modified epoxy resin was then tested using a digital LCR-Meter Peaktech 2170 with a four-wire setup was used to measure the resistance in three different directions.

The conductivity was determined in three directions.

The TUHH analysis finding that, “The mean conductivities of the samples in 0° direction are 0.76 S/m and 0.87 S/m in 90° direction. The standard deviations overlap. The material therefore has an isotropic in-plane conductivity.”

Furthermore, wile many nanomaterial concentrates have struggled to be effectively dispersed in polymer mixes, the TUHH researchers found that a homogeneous distribution of NANO EPO-58 could be achieved without agglomerations.

Epoxy resins have long been the ‘go-to’ solution for flooring systems, but with the addition of nanomaterial concentrates, they can be made stronger and more crack-resistant, as well as thermally and electrically conductive.

NANO EPO-58 shows that nanomaterial research can provide real results for use in epoxy resin flooring systems.

Photo credit: NANOCHEMIGROUP