Like other parts of the chemical industry, resin and plastics manufacturers have long known about the importance of research and development.

With extensive R&D, manufacturers are able to improve the rheology, strength, durability, and flexibility of a material. They can also alter its thermal or electrical conductivity, lower its carbon footprint, or improve its recyclability. Whatever the modification, the need to constantly adapt and improve products is crucial to business success.

Recently, there has been considerable progress in using nanotechnology to improve resins and plastics. This has produced exceptional results, but too often, the final output has remained in the laboratory where it was developed.

While news of these advances is published in scientific papers, their application in the industrial processes for manufacturing resins and plastics is often delayed, or the results are only a generic solution for the wider polymers industry.

Instead, what many manufacturers need is direct research to problem solve a specific issue in an individual resin or plastic. A way to focus scientific analysis into real-world problems in industrial sectors.

With the construction of its nanomaterial research centre, the Prague-based company NANO CHEMI GROUP, has found a way to directly connect industrial manufacturers of resins and plastics with nanotechnology specialists.

This means that a producer of industrial polymers can contact NANO CHEMI GROUP with a specific requirement for one of their products and, working in consultation with nanomaterial scientists, can devise an approach to apply nanotechnology to achieve any desired improvement.

NANO CHEMI GROUP (who sponsor this website) has already cooperated with numerous companies to use nanotechnology to boost the thermal conductivity, chemical stability, strength, abrasion resistance, electromagnetism, ultraviolet protection, or other properties in resins and plastics.

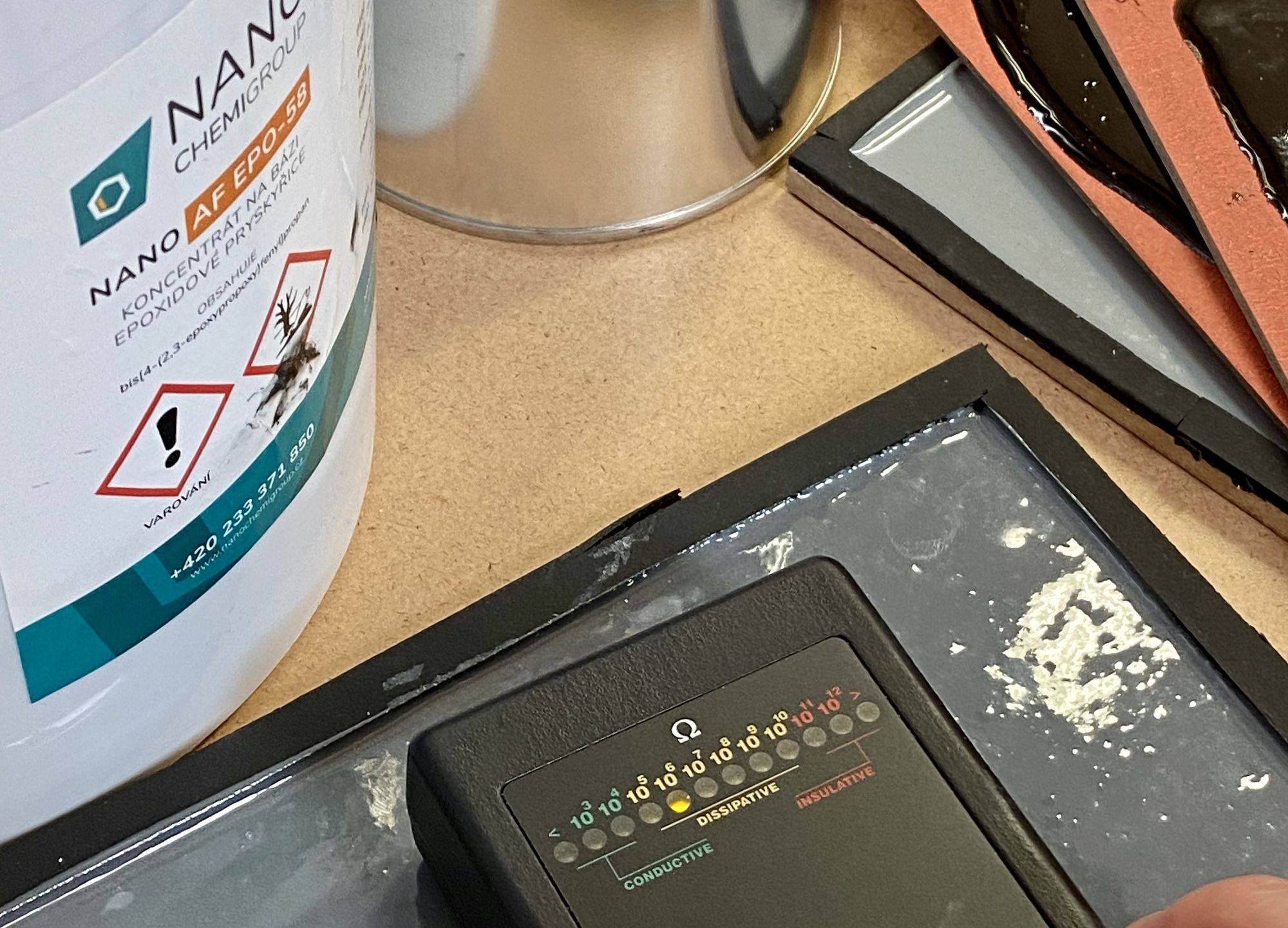

One key example was a client who approached NANO CHEMI GROUP with an epoxy resin product for use in flooring systems. While the product had many excellent attributes, it lacked the electro conductivity needed to be used in electrostatic discharge (ESD) flooring.

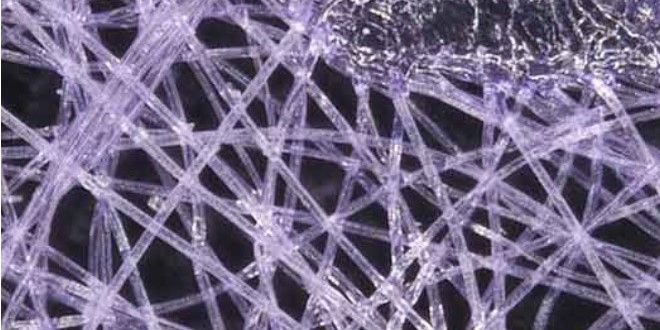

Working on this specific problem, nanomaterial scientists created an industrial concentrate which consisted of a mixture of bisphenol A/F epoxy resin and 0,5 wt.% carbon nanomaterials which permanently increased the polymers antistatic properties.

The low concentration of nanomaterials applied (only 0.05 wt.% single-walled carbon nanotubes) also meant that the resin lost none of its original properties.

The company also has a range of ‘off the shelf’ products available to improve the properties of materials such as methyl methacrylate, polyester resin, phenyl formaldehyde resin, PC-granulate based solution, as well as coatings.

You can see the full product range on the NANO CHEMI GROUP webpage.

With the construction of a nanomaterial research centre designated solely for industrial raw materials, NANO CHEMI GROUP is able to design tailor-made solutions for industrial manufacturers with even shorter lead times.

At a total cost of more than €1.3 million, the laboratory will be fitted with cutting-edge equipment, such as nanomaterial analysers, microscopes, mixers, milling machines, and devices for measuring the chemical, mechanical, and rheological properties of resins and plastics.

Such is the importance and belief in the project, that the company has already secured more than €650,000 in EU funding. Support that will provide real improvements to European manufacturers, with patent pending on its plastics modification technology.

“Our goal is R&D to create materials and solutions that will be used in the resin and plastics production sector,” explains Alexandra Chepak, NANO CHEMI GROUP’s market development manager. “We are not interested in R&D itself, instead we want to bridge the gap between laboratory work and real cases in the true manufacturing sector. We are a commercial organization. We want our solutions to be realized in practice – a usable application of nanotechnology for resins and plastics.”

If your company has a technical task or desired improvement for one of its products, or if you have a product that requires additional testing, then please get in touch with NANO CHEMI GROUP at info@nanochemigroup.cz or call +420 233 371 850.

More information about the company’s research projects and product range can be found at NANO CHEMI GROUP.

Photo credit: L N on Unsplash, feiern1 from Pixabay, L N on Unsplash, & NANO CHEMI GROUP.