In recent years, there has been a great deal of research into the use of nanoadditives in polymer mixes, with various studies finding ways to amend, improve, and boost composites with small amounts of nanoscale raw materials.

As the industry journal Nanowerk explains, “Studies have shown that they [carbon nanoparticles] can increase required mechanical properties with relatively small addition amounts, all the while allowing the final material to be electrically conductive and piezoresistive [so that conductivity can be changed with mechanical stress] in nature.”

But the report also notes the challenge of applying nanomaterials into polymers on an industrial scale, stating that, “… carbon nanoparticle incorporation into large scale production is problematic, requiring intensive facility upgrades.”

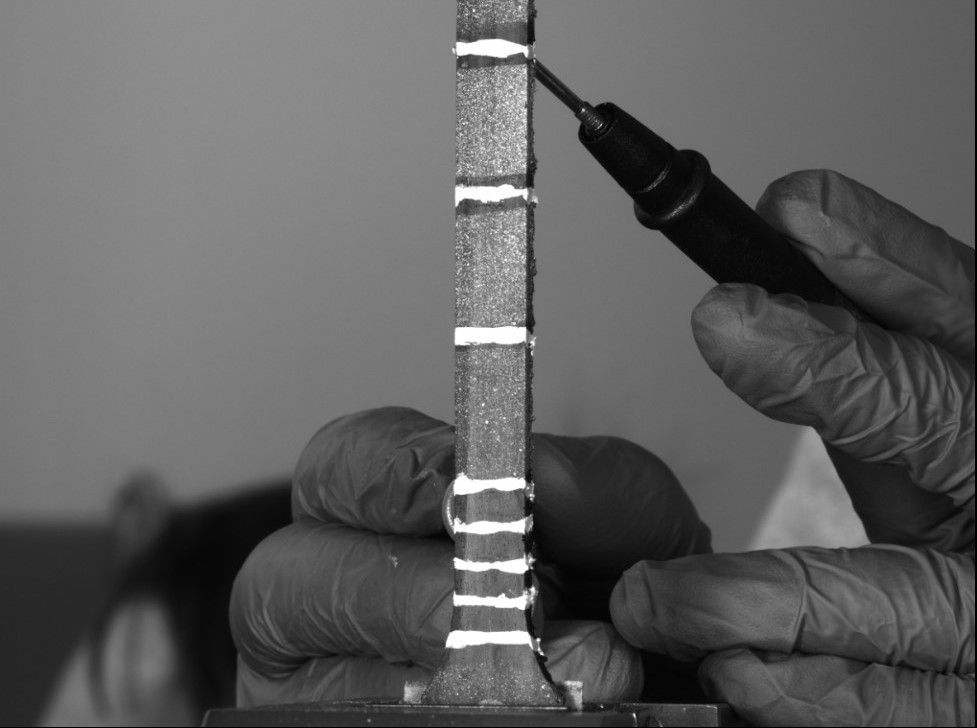

To help remedy this a research team from the Center for Design, Manufacturing and Materials at Skoltech, has made a breakthrough which allows polymer matrices to self-diagnose through the production process. The method is claimed to be inexpensive and easily adoptable, allowing for the easier inclusion of carbon nanoparticles into industrial epoxy masterbatches.

“… we decided to use masterbatches and industrially available, inexpensive manufacturing techniques [because] masterbatches can be stored, transported and incorporated into large scale production routes without the necessity of expensive overhauls,” said the study’s author, PhD student Hassaan Ahmad Butt from the research group of Professor Sergey Abaimov. “Almost every facility dealing with thermoset polymers has a simple mixer.”

“The study examines how the addition of carbon nanoparticles can change the electric conductivity of polymer matrices and how this itself can change during mechanical loading, be monitored, and thus related to the deformation the material is experiencing,” announces the university press release. “In turn, this cuts out the need for complex monitoring techniques, with a simple multimeter being able to determine the answer.”

As a result, a polymer composite with nanoadditives is able to provide its own data, potentially allowing for the removal of expensive sensors that up until now have been required to ensure that raw materials are being mixed accurately. This could even be true when producing weight sensitive composites, such as for aircraft parts.

The study has now been published in the journal Composite Structures, where it states that, “Piezoresistive self-diagnostic nanocomposites have been displayed to be successfully produced using Carbon Nanotube (CNT) masterbatch technology. They display the ability to sense tensile strain and provide a possibility to replace traditional sensors for composite structural health monitoring. Industrially scalable technology and techniques can be used for manufacturing, making them functional, economical, and health hazard-free.”

“The materials are unique in the fact that they can be scaled up into structures or scaled down to attach as separate miniature sensors,” said Hassaan.

The study’s author also believes that the process will be easily adaptable and economic for industry use, as it requires near identical production processes without making changes to the initial raw materials. In this way the manufacture of electromagnetic shielding, electric circuit printing, and specialized temperature and humidity sensors could all be incorporated with the new technique.

It is also possible that the production process could be amended to also include pultrusion and vacuum infusion processes.

Another polymer mix that is growing rapidly thanks to the addition of nanomaterials is the epoxy resin sector.

Epoxy resins have already established key roles as raw materials for the manufacture of paints, coatings, varnishes, floor coverings (including Electrostatic discharge – ESD – floors), adhesives, primers, and sealants.

However, the ability to include nanoadditives into the mixtures has allowed epoxy resin producers to enhance their products by increasing the strength, adjusting electrical and thermal conductivity, improving abrasion resistance and chemical stability, as well as simply reducing costs.

This has broadened the range of uses for this already versatile material as well as enabling the production of specialised epoxies, with tailormade properties.

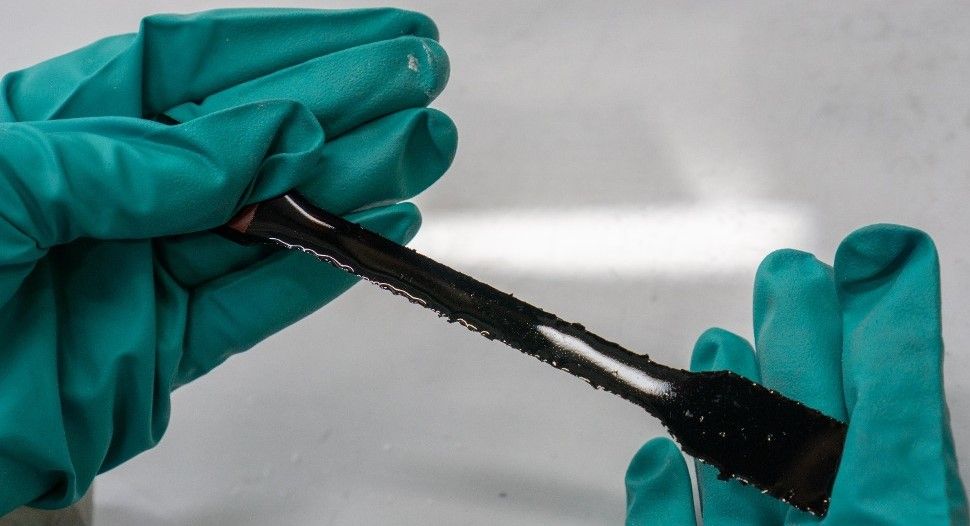

One such example is NANO AF EPO-58, a concentrate which consists of a mixture of bisphenol A/F epoxy resin and 0,5 wt.% carbon nanomaterials.

NANO AF EPO-58 is produced by the Prague-based company NANO CHEMI GROUP (who sponsor this website). It is a product that can be manufactured to order, so as to include specific parameters as required by the customer.

This means that NANO AF EPO-58 can be modified to suit a variety of materials, such as MMA and FF resins, polymers such as PU, PP, PC, PVC, etc., as well as rubbers, paints, varnishes, silicones, gypsum and more. The customer can also specify the property that requires adjusting, for example, electrical conductivity, electromagnetic properties, thermal conductivity, expansion, toughness, strength, elasticity, abrasion resistance, etc. and then list to what degree of change is required.

Progress in the use of nanomaterials in polymers is ongoing. Not only do they provide a boost to the final products, it seems that they can now also improve their own production process.

No longer kept in the domain of the research lab, nanomaterials have now firmly established themselves as a key raw material for industry.

Photo credit: Skolkovo Institute of Science and Technology (Skoltech), Ricardo Gomez Angel on Unsplash, & NANO CHEMI GROUP