Nanotechnology is a disruptive technology, as it upsets the conventional approach to manufacturing and the sourcing of raw materials.

But this is not something negative. As Jack Uldrich explained in his 2003 book, The Next Big Thing Is Really Small, “Nanotech is about creating entirely new materials, products, and systems (and therefore markets), as well as making existing products faster, stronger, and better.”

He foresaw how nanomaterial products would be used in sectors as diverse as energy, agriculture, communications, transportation, manufacturing, electronics, and health care. He also correctly predicted that nanotechnology would be involved in more than $1 trillion worth of products in America alone, and that the nanotechnology industry that would help create as many as two million jobs.

However, he did make at least one mistake, as he advised business leaders to become involved in nanotechnology before “the buzz dies down”.

Almost twenty years later and it is clear that the influence of nanotechnology is not going away, at least not in our lifetimes. This is because the advantages that nanomaterials have over conventional raw materials are permanent.

Nanomaterials can create better products, meaning that less traditional feedstocks are needed. This saves money and also reduces the use of unsustainable materials. As Neil Gordon, Former President of the Canadian Nanobusiness Alliance, notes, “If we can offset a significant percentage of bulk materials with nanomaterials that are lighter, stronger, more electrically conductive, superparamagnetic, tunable optical emission, more porous, better thermal insulating, and less corrosive materials and coatings, we may be able to considerably reduce the overall consumption of steel and other principal materials.”

Evidence of the improvements that nanotechnology is having on even the most basic materials is clear. Two of these are disruptive advances are the application of nanotechnology in resins and the use of nanomaterials in coatings.

Nanotechnology in Resins

Applying nanomaterials in resins is a process which can provide properties of electrical conductivity.

For example, the resin can be impregnated into a durable, technical paper, which is then used to protect the wood in furniture, such as tables, counters, or work benches. It is a nanotechnology which solves the issue of ESD.

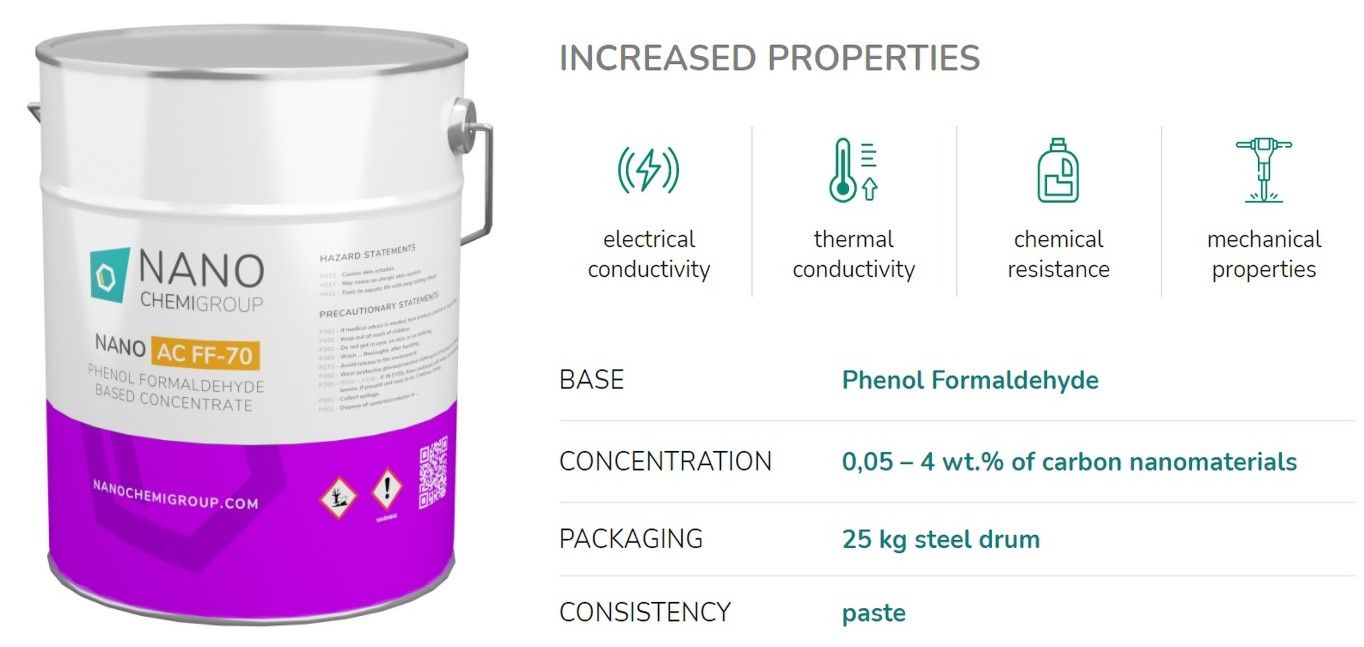

Specifically, the nanotechnology is supplied in a product called NANO AC FF-70. Created by raw material experts at NANO CHEMI GROUP (who host this website), the additive was devised for use in research laboratories where electrical equipment was at risk of damage from ESD. The manufacture of the chairs required the use of a concentrate which consists of a mixture of phenol formaldehyde resin and 0,05 – 4 wt.% of carbon nanomaterials - depending on the formulation.

Concentrate NANO AC FF-70 is widely used in polymers to permanently increase antistatic, dissipative or electroconductive surface and volume properties.

To learn more about this product, visit NANO CHEMI GROUP.

Nanotechnology in Coatings

Nanotechnology can also be applied to coatings to extend the lifespan of both the coating and the object it is protecting.

For example, coatings which contain nanomaterials can provide properties, such as high elasticity, fast drying, increased indentation resistance, no expansion after contact with water, and high water vapour permeability.

There are also a number of environmental benefits to using nanomaterials in coatings, as their improved performance can result in a thinner layer being required, reduce the number of layers applied, or reduce the need for toxic solvents and VOCs. Their surfaces can also be self-cleaning or ‘easy-to-clean’, lessening the time and energy spent on maintenance and lowering the amount of detergent and cleaning agents used.

Nanotechnology can also make coatings transparent, improve opacity, or enhance colour effects.

Because of these benefits, nanomaterial-based coatings are now used on automobiles, ships, in the aerospace industry, on household appliances, in buildings (both interior and exterior), on military hardware, and on machinery.

One such coating which takes advantage of nanotechnology is NANO CR Coating; a chemically resistant paint for use in aggressive environments.

Made by the Prague-based company NANO CHEMI GROUP (who sponsor this webpage), NANO CR Coating is an epoxy-based paint designed specifically for use on trucks, tanks, and equipment for storing, transporting, or using high concentrations of industrial materials. such as salts or acids.

By protecting expensive vehicles, storage containers, and mining equipment, the coating lowers long-term production costs and actually saves money.

“Other laboratory tests on a combination of nanomaterials in epoxy coatings have shown promising chemical resistance against KOH, NAOH, SO4, Chlorine, phosphoric and sulphur acids,” explains Alexandra Chepak, NANO CHEMI GROUP’s Market Development Manager. “

For many manufacturers, using nanomaterials in place of historically used feedstocks means stepping into the unknown. A disruptive process of moving away from conventional raw materials and supply chains. It is a revolutionary approach to manufacturing that can create better products, form unique selling points, become more sustainable, and lower costs.

Nanotechnology is having a larger and deeper impact on manufacturing, industry, and scientific advance than anyone could have predicted. And while this may be disruptive, manufacturing is all the better for it.

If you would like to learn more about nanotechnology's influence on manufacturing then maybe read: Polycarbonate and Nanotechnology – An Excellent Combination or Enhanced Materials and Products with Four Clever Nanotechnologies.

Photo credit: Kateryna Babaieva from Pexels, Brett Sayles, Alexander Drummer, Dewald Van Rensburg from Pixabay, & NANO CHEMI GROUP