Anyone who follows the news in manufacturing and trade journals is aware of all the latest trends and buzzwords. From big data to industry 4.0 to the Internet of Things, the world of production and industry is, we are told, being turned on its head by what modern technology can achieve.

However, to a large extent, these changes have been less revolutionary than advertised. Although the influence of increased computing power and faster telecommunications has resulted in a rush towards increased automation. Having larger computers may have increased efficiency, but industry still makes the same products.

Big data may decrease production costs, but the paint, plastic, concrete, ceramics, glass etc. remain unchanged.

The same cannot be said for nanotechnology, which is changing not only how products are made, but is also improving raw material quality, lowering manufacturing and application costs, and resulting in an all-round, better end-product.

So, when looking at industry trends, instead of focusing on digital technology, shouldn’t we be talking more about nanotechnology?

For example, all too frequently, the term nanotechnology is linked to quantum computing, artificial intelligence, and electrical devices small enough to fit under a thumbnail.

Certainly, the use of graphene and carbon nanotubes (the best electrical conductors known to man) are boosting processing speeds and enabling ever smaller chips and longer-lasting batteries. But surely, the true revolution for nanotechnology has been its influence on making things.

And what things they’ve made!

Crack and fade resistant paint, anti-static plastics which reduce the risk of fires and explosions when storing and handling combustible materials, improved sound protection for machinery, increased durability for rubbers, reduced weight for car and aircraft parts (which lowers fuel consumption and helps lower environmental impact), advanced metallurgy used for use in spacecraft and military hardware, cutting-edge sporting equipment, such as tennis racquets, bicycles, football, yachts, and archery bows, more robust mobile phone casings, flexible touch screens, more efficient fertilizers (which limit run-off and prevent algal blooming), improved pesticides, fungicides, and herbicides, better animal feed, and targeted pharmaceuticals, to name just a few.

But how can manufacturers achieve these improvements without an advanced understanding of nanomaterials?

There are two straight-forward steps for utilising what nanotechnology has to offer; off-the-shelf nanoproducts and design-to-order nanotechnology.

Off-The-Shelf Nanotechnologies

This includes a range of raw materials and input products which can easily be added during current manufacturing processes to lower energy costs, improve performance, and add unique selling points.

Examples of off-the-shelf nanotechnologies currently on the market include:

NANO AP PCG-23; a modified PC granulate (polycarbonate) that contains 0.12 – 0.24 wt.% of carbon nanomaterials.

As well as providing thermal conductivity, boosted mechanical strength, ultra-violet protection, and electro-magnetic properties, this novel nanotechnology also adds much sought-after electro-conductivity.

The damage caused by electrostatic discharge (ESD) can be prevented with the use of conductive thermoplastic compounds that reduce the degree of charge by dissipating electricity away before it can accumulate to dangerous levels.

In the electronics industry alone, annual losses due to ESD are estimated at more than $40 billion.

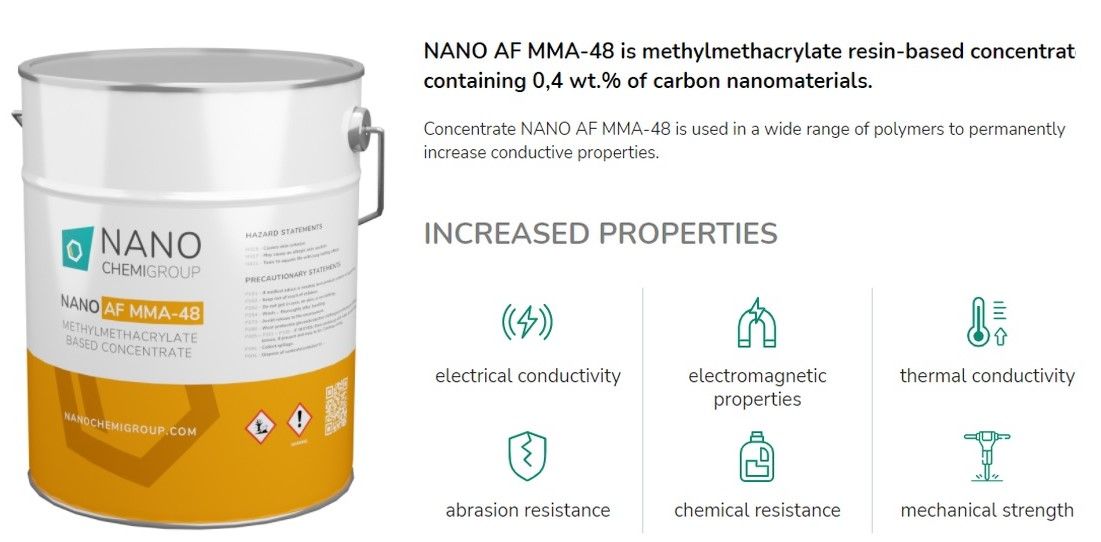

Developed by NANO CHEMI GROUP, the product NANO AF MMA-48 is a further example of nanotechnology's influence on manufacturing. Simply put, it is a methyl methacrylate (MMA) resin-based concentrate containing 0,4 wt.% of carbon nanomaterials. However, the application of nanomaterials into MMA flooring systems makes a significant difference.

By using such a low weighting of nanomaterials in the polymer the flooring does not lose any of its original features, while the polymer still gains additional properties, such as quick drying, thermal conductivity, crack and scratch resistance, and increased durability. All while limiting ESD.

To learn more about this topic, read: Nanoadditives Give MMA Flooring Electrostatic Discharge Properties or visit NANO CHEMI GROUP.

Another example of nanomaterials improving construction materials, is their application in gypsum board (also called plasterboard or drywall) in a product called NANO AS GYPS-27.

Made by NANO CHEMI GROUP (who support this website), the water-based concentrate includes a low 0.2 wt.% volume of carbon nanomaterials to not only improve gypsum board’s mechanical strength, but to also provide electrical conductivity.

This protects walls, ceilings, and floors from the dangers of electrostatic discharge, making gypsum board a practical solution for spaces that store or manufacture electronics or flammable goods.

Design-to-Order Nanotechnologies

Tailor-made nanotechnologies occur when a manufacturer knows what it wants its products to achieve and then requests a nanotechnology specialist to develop those features or improved properties.

The range of properties can be wide ranging and multifaceted, and may include advances such as increased impact strength, added antimicrobial properties, thermal conductivity, electromagnetism, UV protection, crack resistance, or electroconductivity.

This approach is founded on close cooperation between a nanotechnology developer, such as NANO CHEMI GROUP, its long-term customer base, and material scientists.

NANO CHEMI GROUP has established business partnerships with the following academic institutions:

· Hamburg Technical University

· The Sumy State University

· The Leibniz Institute for Polymer Research in Dresden

· The Ukrainian Academy of Science

· Heyrovsky University

· The Nanotechnology Centre at the Technical University of Ostrava – VSB-TUO

It is a team that combines a practical understanding of nanotechnology with experience in industrial markets for raw materials. By cooperating with clients and nanomaterial researchers the company has ongoing analysis of how to expand the use of nanomaterials in rubber, concrete, fabrics, construction materials, and industrial resins.

Unfortunately, these raw material products and nanotechnology developments are unlikely to make newspaper headlines.

Instead, media attention will continue to wonder at the technological advances that can create ever-smaller mobile phones and a refrigerator which can self-order milk.

While these achievements may one day make for a better world, those who work in manufacturing and procurement, know that the real technological breakthroughs of the last two decades are being made with nanomaterials.

Photo credit: Unsplash, Unsplash, Ulrich Dregler from Pixabay, Unsplash, Unsplash, & NANO CHEMI GROUP