Epoxy resin manufacturers are discovering more and more about the practical role that nanomaterials can play in enhancing their products.

Nanomaterial researchers are finding that a wide variety of properties can be added with only a small concentration of nanoproducts.

One of the most recent studies has found that nanoparticles of silica can significantly increase the hardness and physical strength of epoxy resin when used in flooring.

Previous work on the inclusion of nanoadditives to epoxy resins (as well as other polymers) has always struggled to ensure that the nanomaterials were sufficiently and evenly spread throughout the mix. Failure to do so could impair the nanoadditives’ effectiveness.

However, today there are multiple approaches to solving this issue, including novel methods which enable the application of nanomaterials only on the surface of a substance (such as a polymer) where it may be of most use. This can create considerable savings as the quantity of nanomaterials required are reduced to those required only on the top layer of a material.

In this latest research, the study’s authors were able to fully mix the SiO2 nanoparticles in the epoxy resin by pretreating them with a coupling agent in acetone.

After this had been added to the epoxy resin, and a thorough mix had been obtained, the acetone was then removed to avoid it impacting the viscosity of the final flooring product.

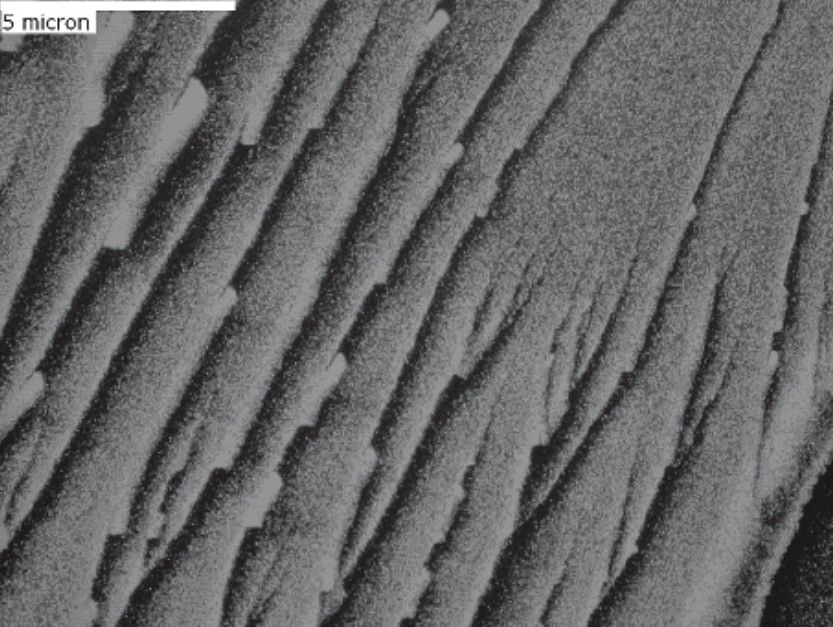

The study has now been published in the journal Current Chemistry Letters, where a team from the Engineering Research Institute in Tehran explain how, “Nano silica was treated by a coupling agent [γ-Aminopropyltriethoxysilane (Amino A-100)] due to its effectiveness and commercial availability. … SEM observations of cured samples revealed that the nano silica was completely dispersed into polymer matrix into nanoscale particles. Thermal and physical properties of prepared samples were investigated, and data showed improvements in physical and mechanical properties of the flooring samples in comparison with unfilled resin.”

The study concluding that the application of, “… SiO2 nano particles in epoxy flooring formulation as a reinforcing agent which would result in better performance in the industry. According to high active surface and surface- diameter ratio in nanoparticles, they would act as stress concentrators and a binding bridge at the inter-phase.”

While the researchers can rightfully claim the success of their work, it is unfortunate that the nanomaterials tested were unable to impact other key areas where epoxy resins flooring require improvement.

Other processes on the market have already found ways to increase various properties in epoxy resins through the inclusion of carbon nanotubes.

For example, the product NANO AF EPO-58 is a concentrate which consists of a mixture of bisphenol A/F epoxy resin and 0,5 wt.% carbon nanomaterials.

Supplied by the Prague-based company NANO CHEMI GROUP (who sponsor this website), concentrate NANO AF EPO-58 is widely used in polymers to permanently increase antistatic, dissipative or electroconductive properties.

Other attributes that can be improved in epoxy resins include:

· Mechanical properties

· Electromagnetic properties

· Thermal conductivity

· Abrasion resistance

· Chemical resistance

With an increasing number of electrical devices, equipment, and machinery (including those storing digital information) the need for electrostatic discharge (ESD) flooring is growing considerably. While current raw materials for ESD systems are adequate, the application of nanomaterials, in these cases either carbon or silica) can make a significantly better product.

Moreover, as the nanomaterials are able to boost specific properties, it is now possible for manufacturers of epoxy resins and ESD flooring products to source lower quality raw materials (at a lower cost) and then improve them with nanomaterials to achieve a final product of a higher standard at a lower price.

Advances such as this are clearly ground-breaking, not only in the way that they revolutionise the chemical and physical abilities of epoxy resins, but also in how they are revolutionising the economics.

To learn more about how nanomaterials can improve epoxy resins or lower the cost of epoxy resin flooring systems, visit NANO CHEMI GROUP or call +420 233 371 850.

Photo credit: Hayley Catherine on Unsplash, NANO CHEMI GROUP, Current Chemistry Letters, Catherine Augustin from Pexels, & Li Sun from Pexels