Any expert in the flooring or resin industry can tell you about how versatile and effective methyl methacrylate (MMA) can be.

When applied as a raw material for flooring systems, MMA is safe, strong, durable, decorative or plain, scratch and crack resistant, quick curing, and easy to install.

These parameters make methyl methacrylate an ideal material for flooring systems even though they can be more expensive than their less-effective competitors, such as epoxy resin or vinyl flooring systems.

While MMA flooring is often used in industrial buildings or public spaces it has always lacked properties of electrostatic discharge (ESD) to make it more versatile and widely employed. This can prevent it from being used in hospitals, offices, light industrial units, or warehouses as the build-up of an electric charge in the flooring can damage expensive equipment or electrical devices held in storage. It can also stop it being applied in locations where unstable or flammable materials are being stored or produced, as static electricity could start fires or cause explosions.

However, recent cooperation between NANO CHEMI GROUP (who sponsor this website) and their R&D partners has now solved this problem by developing a nanotechnology which can incorporate carbon nanotubes to MMA flooring systems to provide electrostatic discharge properties.

Nanomaterial additives improve MMA flooring

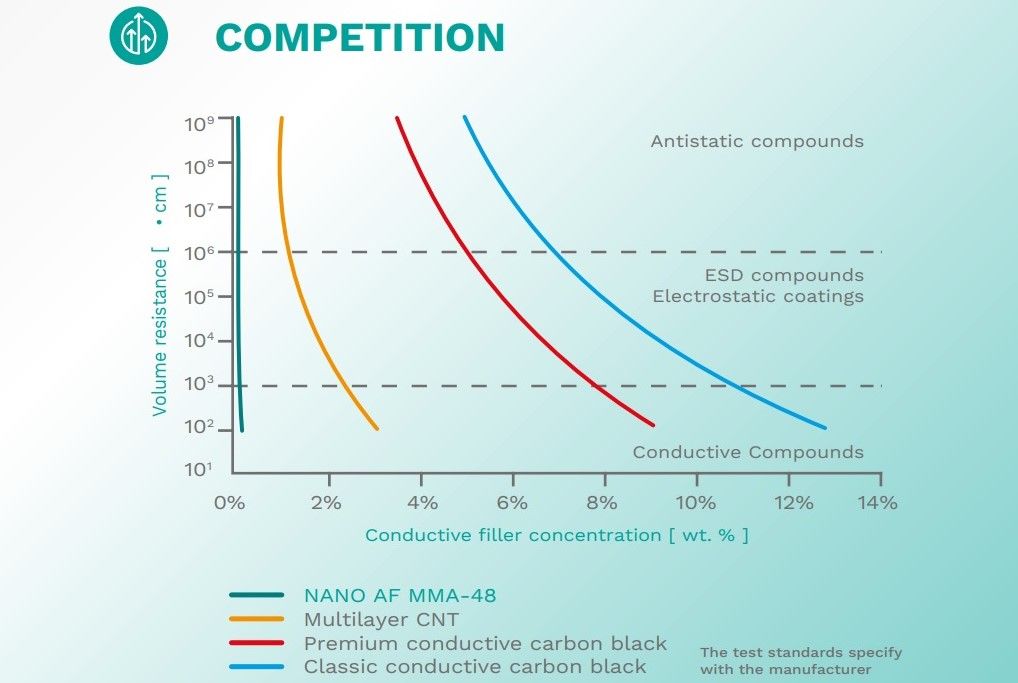

The new product is called NANO AF MMA-48, a methyl methacrylate resin-based concentrate containing 0,4 wt.% of carbon nanomaterials.

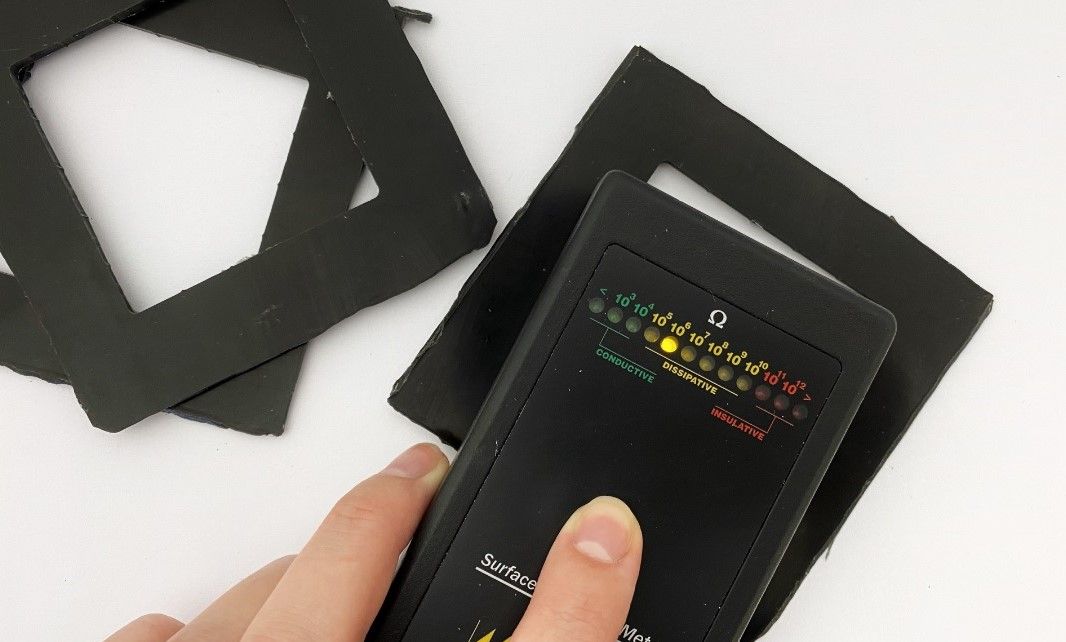

While the normal loading rate of the nano additive consists of as little as 0.05 - 0.025 wt.%, samples conducted with a Wolfgang Warmbier, Surface Resistance Meter SRM110 reported the surface resistance of being between 106 ohm/sq and 107 ohm/sq, proving the material as an effective dissipator of electricity.

The result is a raw material that is highly suitable and cost effective for use in making ESD and ASD floorings.

Nanomaterials Do Not Restrict Other Properties

Moreover, the use of NANO AF MMA-48 does not reduce the effectiveness of the original product, which will still cure quickly (even in cold or damp conditions), can still be easily renovated, remains safe, strong, durable and crack resistant.

Nanomaterials Can Reduce Costs

An additional advantage of using nanoadditives in MMA mixtures is the savings made to production costs and time, primarily because only a single conductive layer is required to make ESD flooring, as opposed to the more conventional two layers.

Furthermore, with additional research, it is possible to purchase cheaper supplies and then, by applying a nanoadditive concentrate, to obtain the mechanical and conductive properties of more expensive resins.

Consequently, manufacturers of methyl methacrylate are able to reduce their costs for raw materials, labour, and energy, as well as shorten installation time, and cut expenses on logistics and storage, all while producing a resin with a better conductive performance.

This means that an investment in nanoadditives could actually save more money than it costs.

While this discovery will not make epoxy resin and vinyl flooring systems redundant, the application of carbon nanomaterials in MMA does present some new economics in how to produce ESD floors.

To find out more about NANO AF MMA-48, visit the NANO CHEMI GROUP website, or call +420 233 371 850 and ask about how NANO CHEMI GROUP’s specialised nanoadditive solutions can be modified to suit the particular needs of your products.

Photo credit: NANO CHEMI GROUP, Logan Stone on Unsplash,