Gypsum board, plasterboard, drywall, even Gibraltar board, wherever you are and whatever it is called, the use of calcium sulfate hydrate (CaSO4.2H2O) sandwiched between two sheets of paper is a versatile and practical building material.

With its quick and easy installation combined with relatively low cost, gypsum board is a go-to solution for walls, ceilings, and even floors, in offices, homes, storage facilities, and light industrial units. However, with the growing number of electronic devices and equipment being used in these spaces, the need for protection against sudden electrostatic discharge is growing.

Electrostatic discharge (ESD) caused by friction between two objects, such as walking across a carpet or a box rubbing against a wall can create a release of electricity which can destroy expensive electronic devices, erase electronically stored data, damage computer systems, or even ignite flammable or combustible substances.

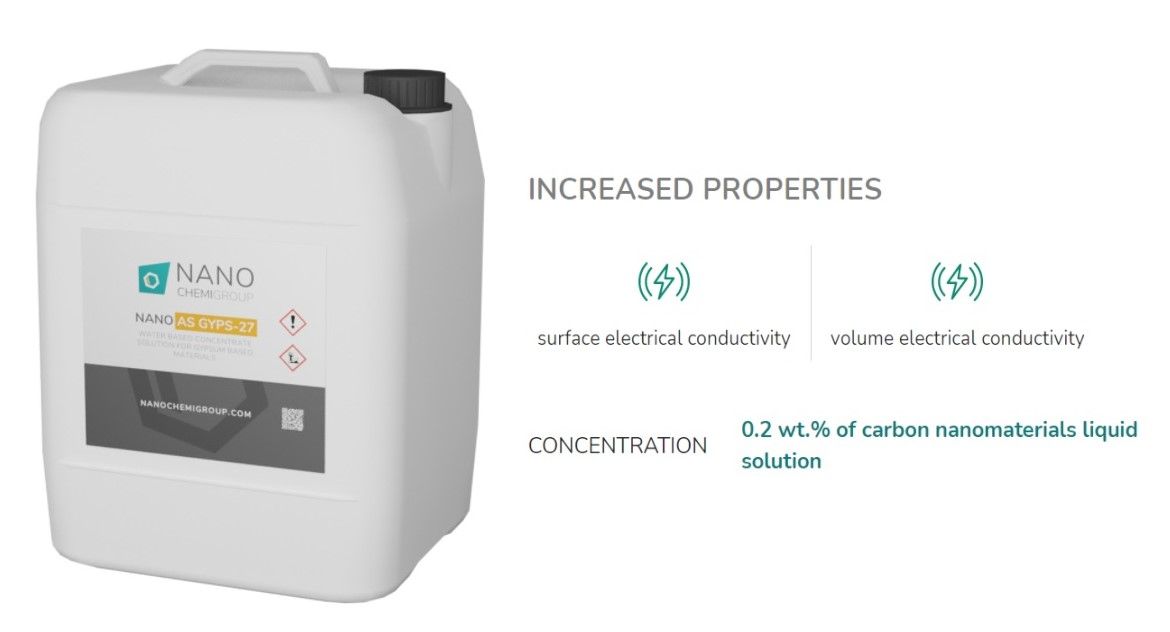

ESD properties can be provided with a carbon nanomaterial concentrate added to the gypsum board during the manufacturing. It is a process which provides much sought-after surface and/or volume electrical conductivity, adding value to building materials by providing a safer and more protective wall, ceiling, or floor.

This nanotechnology is called NANO AS GYPS-27 – a water-based concentrate solution for gypsum-based materials.

It has been designed by NANO CHEMI GROUP in cooperation with a client who wished to develop a gypsum board for a raised flooring system with improved mechanical and conductive properties.

By including nanomaterials, the gypsum provides good electrical conductivity at both its surface and in its volume, creating a flooring system which is suitable for use with hazardous substances or for the production and storage of electronic devices.

Furthermore, because only 0.2 wt.% of carbon nanomaterials are required to provide the gypsum board with electrical conductivity, the gypsum board loses none of its original properties, such as sound protection, convenience, quality, and strength. In fact, the inclusion of carbon nanomaterials can even boost mechanical strength.

With further research, this technology may also be adapted to other building products beyond gypsum board, such as gypsum shaftliner panels, and glass mat gypsum panels, as well as abuse-resistant and impact-resistant gypsum panels.

Improving gypsum board is not an easy task, as it is already well-known for its many superior properties – most notably its fire resistance.

This is because the gypsum is located between two layers with a small amount of crystalline water. As any fire approaches, the water vaporises creating an instant cooling effect - a bit like a built-in sprinkler system. Meanwhile, the gypsum itself, will only catch fire at very high temperatures, making gypsum board a relatively fire-resistant product.

Alongside these fire safety features; gypsum board also has good impact strength and sound protection. It can also be a recycled product, as some 30% of all gypsum raw material is sourced from power plant waste.

Adding the extra property of electrical conductivity can make a truly exceptional building material, while still maintaining its low cost.

To find out more about how nanotechnology can boost the properties of gypsum or to find out how NANO AS GYPS-27 can improve your construction materials and industrial products visit NANO CHEMI GROUP or call +420 233 371 850.

Photo credit: freepik, & NANO CHEMI GROUP