Despite all of mankind’s advances in technology and material research, wood remains a truly incredible resource.

It is strong yet inexpensive, can be lightweight or heavy, can be rigid or flexible, is easy to work with, makes a good thermal and sound insulator and requires little maintenance. Even more importantly in the modern world, it is renewable, recyclable, and sustainable.

Wood also has low electrical conductivity – and while this can be an advantage in some situations, as it can act as an insulator against electric shocks, it can also be a disadvantage for those who manufacture fine electronics or for those conducting research with delicate electronic equipment.

The danger with using wooden furniture is that electro-static can build up from tiny amounts of friction between items on the bench or from a person sitting in a chair at the bench.

If left untreated, the electricity can suddenly discharge, damaging or destroying any electrical equipment in the vicinity. This is especially true for modern semiconductor devices and components as electrostatic discharge (ESD) can corrupt devices, wiping out irreplaceable electronically stored data.

Each year, the cost to the electronics industry through ESD is estimated to be more than $40 billion.

Additional high-risk areas include those with explosive or combustible items, as a single spark can cause terrible damage and personal injury.

When used during research or when producing electronics, it is important that the furniture used protects against the build-up of static electricity.

Solving the issue of ESD is possible with the application of carbon nanomaterials in resin. The resin can be impregnated into a durable, technical paper, which is then used to protect the wood. It is a process that uses nanotechnology to provide properties of electrical conductivity in furniture, such as tables, counters, or work benches.

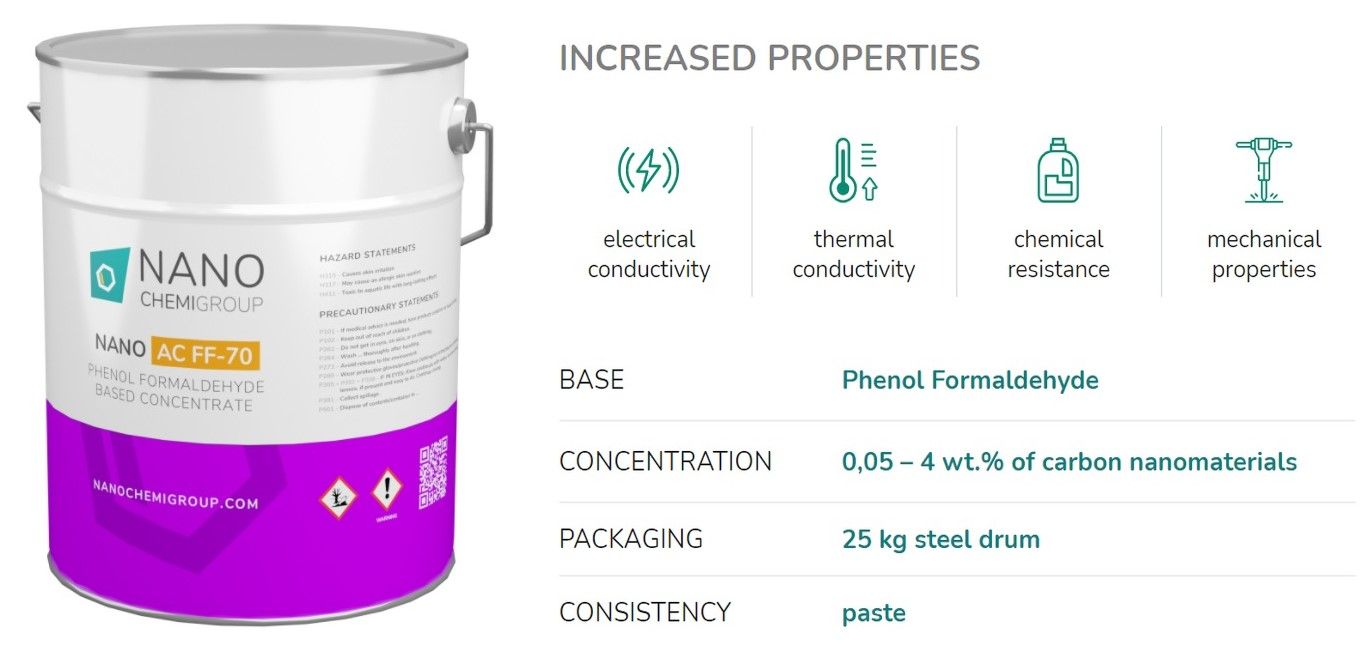

Called NANO AC FF-70, the product was specifically devised for use in research laboratories where electrical equipment was at risk of damage from ESD. The manufacture of the chairs required the use of a concentrate which consists of a mixture of phenol formaldehyde resin and 0,05 – 4 wt.% of carbon nanomaterials - depending on the formulation.

Concentrate NANO AC FF-70 is widely used in polymers to permanently increase antistatic, dissipative or electroconductive surface and volume properties.

It was created thanks to NANO CHEMI GROUP’s team of raw material supply experts and their cooperation with numerous nanotechnology researchers based at academic institutes across Europe.

Combining know-how in nanomaterials and experience in the supply of feedstock for manufacturing allows the company to develop nanotechnologies with practical solutions for industry.

Manufacturers can then choose from one of NANO CHEMI GROUP’s off-the-shelf products for coatings, plastics, gypsum board, and rubber, or request the development of a made-to-order nanotechnology for their own product range.

“Each specific solution is created to suit each individual requirement,” says Lev Lyapeikov, NANO CHEMI GROUP’s Product Development Manager. “Our approach provides better material performance and efficiency, as well as lower costs, compared to other microparticles and nanofibers.”

If your products would benefit from additional ESD or if you would like to learn more about how nanomaterials can provide resins and polymers with added strength, chemical resistance, or other properties then please visit NANO CHEMI GROUP.

Photo credit: National Cancer Institute on Unsplash, RephiLe water, Yolk CoWorking - Krakow, & Chris Ried