Researchers have combined plant-based nanoparticles and water to form an ‘eco-superglue’ that is cost effective and sustainable, yet still forms a very strong bond.

While other studies have already created incredibly strong, environmentally friendly, and low-cost glues, the ability of this work to provide all three criteria in one product is truly exceptional and may be a landmark moment for the adhesive industry.

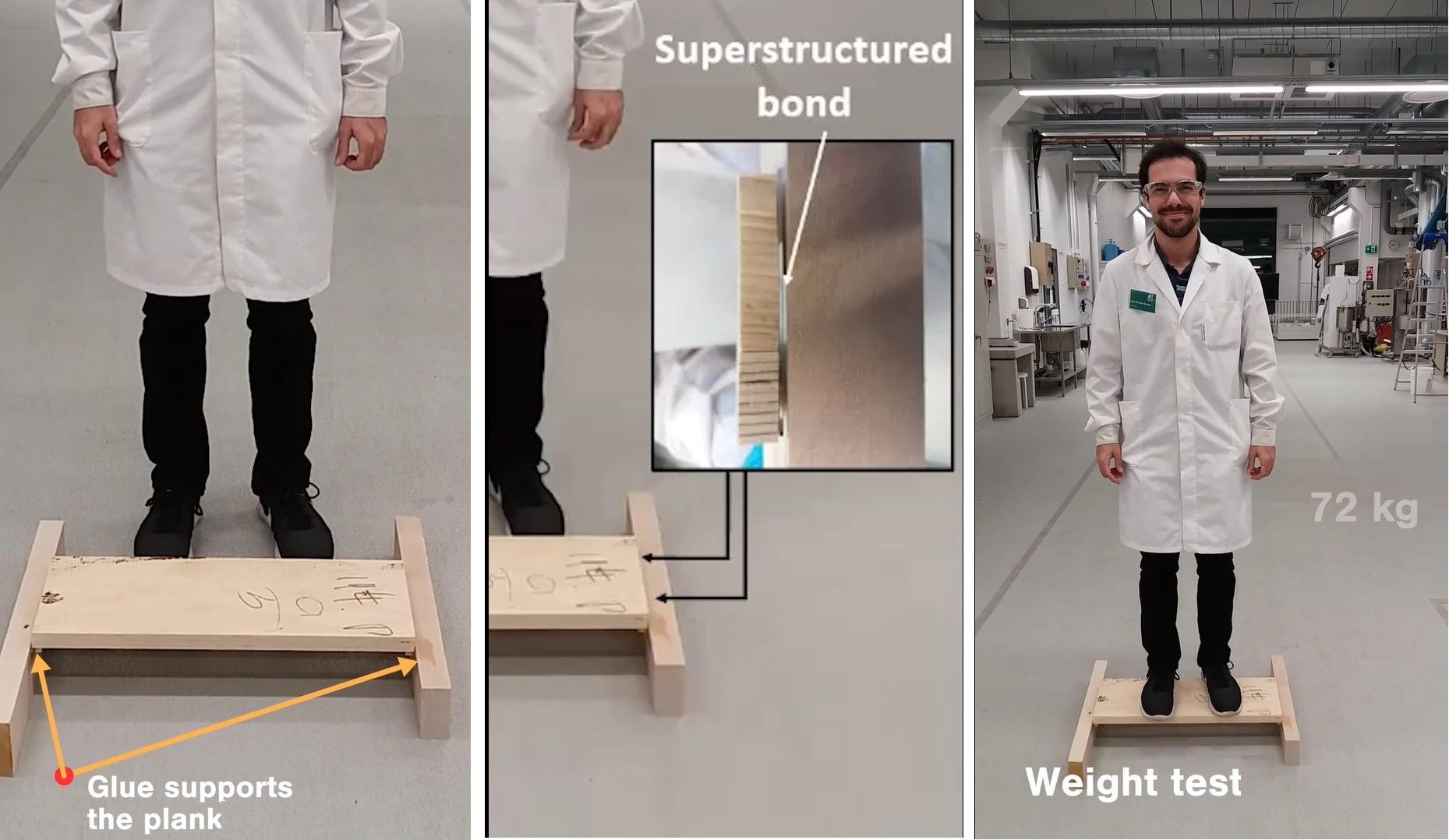

“The ability to hold this amount of weight with just a few drops is huge,” says Dr Blaise Tardy, one of the study’s co-authors, “especially from a natural plant-based solution.”

As the Aalto University press release explains, the new eco-superglue is not based on a chemical bond like currently available commercial superglues, but instead, “… develops its full strength in a preferred direction, similar to ‘peel and stick’ adhesives.”

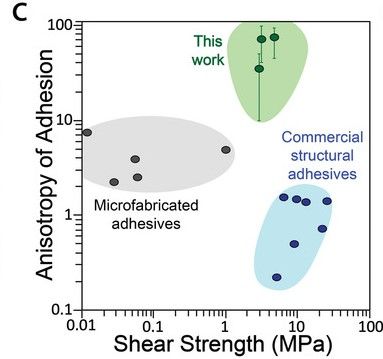

Explaining that, “When trying to separate the glued components along the principal plane of the bond, the strength is more than 70 times higher when compared to the direction perpendicular to that plane. All of this means that just a single drop of the eco-glue has enough strength to hold up to 90 kg weight, but can still be easily removed by the touch of a finger, as needed.”

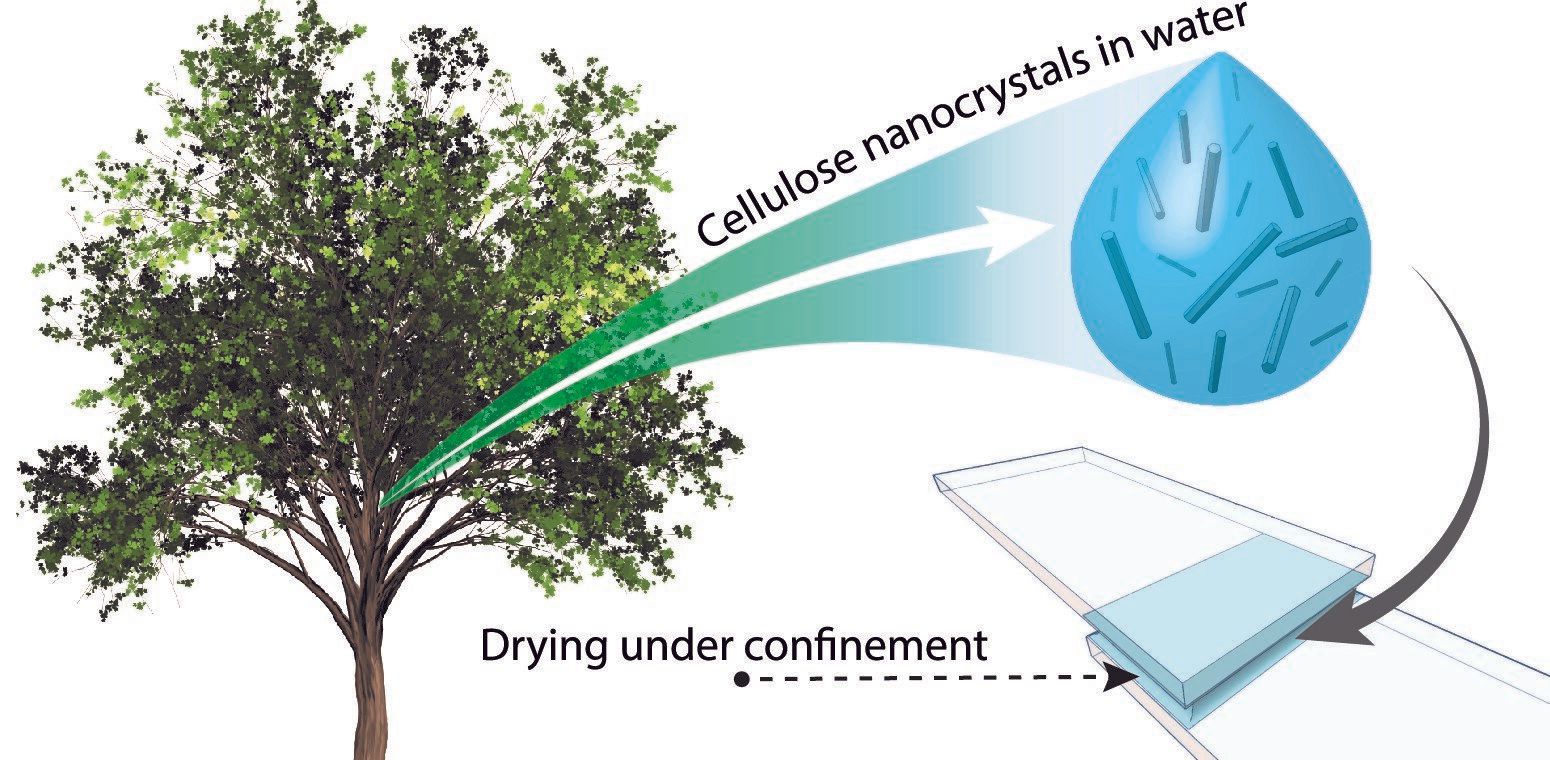

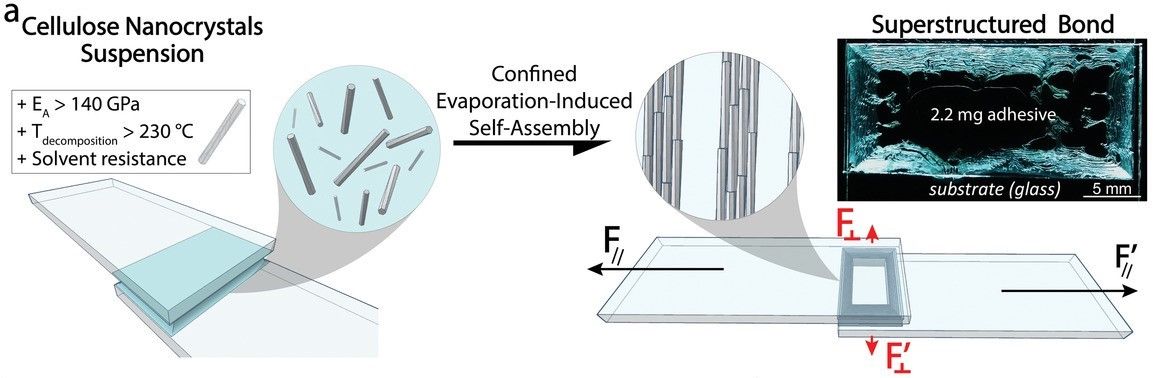

Specifically, the glue is made up of, “… aqueous dispersions of cellulose nanocrystals (CNCs) that form superstructured, adherent layers between solid surfaces upon confined evaporation‐induced self‐assembly (C‐EISA).”

The breakthrough was made following a joint study by material scientists at Aalto University, Sichuan University, the University of British Columbia, and the University of Tokyo. As Professor Orlando Rojas of Aalto University notes, “Reaching a deep understanding of how the cellulose nanoparticles, mixed with water, form such an outstanding adhesive is a result of the work between myself, Dr. Tardy, Luiz Greca, Professor Hirotaka Ejima, Dr. Joseph J. Richardson and Professor Junling Guo, and it highlights the fantastic collaboration and integration of knowledge toward the development of an extremely appealing, low-cost and safe application.”

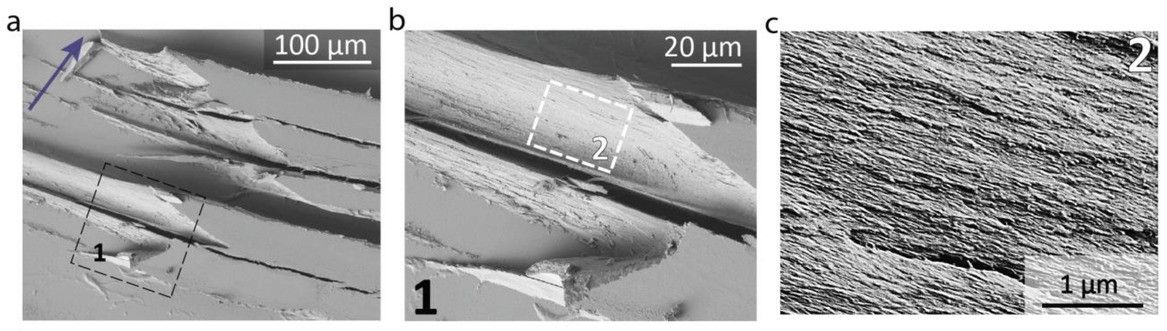

The study has now been published in the journal Advanced Materials, where the researchers state the discovery of a, “… simple self‐assembly phenomenon involving aqueous suspensions of anisotropic organic nanoparticles can induce extremely high, noncovalent adhesive shear strength. C‐EISA resulted in a gel‐to‐solid transition forming multiscaled order, with superstructured lamellae that act in a fashion similar to most dry and reversible bioadhesives found in nature, for instance in setae of insects or geckos. Analogous to natural reversible adhesives, the in‐plane and out‐of‐plane adhesion values diverge by more than 70‐fold.”

Moving forward, the researchers believe that such a strong glue could find useful applications in the microelectronics sector, adhering fragile components. Alternatively, the adhesive’s ‘stick and peel’ properties would make it useful for attaching expensive decorations which must remain in place for only a short period.

However, for now the team are working on how to develop the glue for use in the €40 billion packaging industry, where a strong and re-attachable bond could find many uses.

As Dr Blaise Tardy observes, “Good, green packaging with bad glue still renders the packaging bad.” Before noting the real key to making this adhesive a success, saying, “The truly exciting aspect of this is that although our new adhesive can be sourced directly from residual biomass, such as that from the agro-industry or recycled paper, it outperforms currently available commercial synthetic products by a great many measures.”

While at present the glue requires a curing time of about 2 hours (as the water evaporates away), however the team is confident that this could be shortened and controlled with heat.

But ultimately, what impresses most about this glue, beyond its natural raw materials, its low-cost, and its great strength; is its simplicity. The ability to use plant-sourced cellulose nanocrystals with water to create a cheap, yet strong glue; well that’s something the adhesive industry can get stuck into!

Photo credit: Aalto University, Phys.org, & AdvancedMaterials