Despite the fact that the first carbon nanotube was created in a laboratory less than thirty year ago, manufacturers have been quick to use nanomaterials to improve thousands of products.

However, the task of developing and applying such innovative technology can be daunting and potentially expensive. Consequently, plenty of businesses still struggle to take full advantage of what the nanotechnology industry has to offer.

The issues preventing more manufacturers from using nanomaterials include:

1. Business leaders don’t know what nanotechnology can achieve for their products.

Such a knowledge gap is understandable as media focus on nanotechnology is often only focused 1) how nanomaterials improve medicines and pharmaceutical treatments, and 2) how nanotechnology has improved the electronics industry with quantum computing, smaller smart phones, and the Internet of Things.

In reality, nanotechnology can boost regular raw materials such as polymers, resins, emulsions, coatings, textiles, construction materials, and elastomers. It does this by either improving existing properties, such as making a resin more durable or a coating more scratch resistant, or by conveying additional properties. For example, a polymer can be given electrical conductivity, electromagnetic properties, thermal conductivity and/or ultra-violet protection.

2. Businesses lack testing equipment and production facilities.

Each stage of developing a nanotechnology requires the use of nano-tools to visualize, manipulate, and model materials at the nanoscale, as well as an experienced team to use it.

3. How much value will be added to a product which uses nanotechnology?

Will the application of nanomaterials reduce production or raw material costs? Will it find new customers and markets?

These questions are particularly relevant if the product’s end-user is further down the value chain.

4. Risk analysis and regulations are still an open agenda.

What are the regulations on using nanomaterials? How safe are nanomaterials? Even in the EU, nanomaterial regulation (based upon REACH compliance which governs the supply and application of all chemicals) is still being developed.

5. A large amount of nanotechnology research is government funded. How can businesses with limited budgets consider using nanomaterials without state support?

Nanotechnology research is often associated with wealthier countries. For example, the USA is by far the world leader in the number of nanotechnology patents listed each year.

At the same time, an EU-funded analysis on how nanotechnology is transferred from academia to industry found that developing and applying nanomaterials was much easier depending on where the business was placed.

The 2012 report stating that, “In particular, the United Kingdom and Germany show mature technology transfer structures and the UK also experiences a more developed activity of business angels and venture capitalists in nanotechnologies.”

Almost a decade later and regional differences have reduced dramatically with nanomaterials being more widely produced and nanotechnology applied wherever there is manufacturing. However, the report was also able to outline the biggest challenge facing businesses which wish to develop their products further.

What most manufacturers lack is the capital equipment to produce structures at the nanoscale and the technical knowledge to apply nanomaterials into the desired intermediate products.

Fortunately, as the nanotechnology industry matures, closing the gap between nanotechnology research and its application in manufacturing has now become considerably easier.

Increased interest in nanotechnology and more discerning consumers has led numerous companies to specialise in the development of nanotechnology for specific products.

While a large bulk of research into nanomaterials is still based in academia, companies such as NANO CHEMI GROUP are interested only in creating nanotechnologies which have a use in end-products. They aid manufacturers in finding solutions based on nanomaterials with a market need.

Nanotechnologies can be designed-to-order

Today, manufacturers need only request the additional properties they would like their products or intermediates to possess and leave the research, development, testing, regulatory compliance, and sourcing of nanomaterials to the experts.

Following a short consultation with nanotechnology process designers, clients of NANO CHEMI GROUP (who support this website) are able to solve specific manufacturing issues, improve end-products, save input costs, reduce product application times, lower energy bills, and/or provide unique selling points.

In this way, manufacturers can improve their products, increase their sales, and expand into new markets with minimum risk.

Nanotechnology need no longer be mysterious. Instead, it can be used to design raw materials that are tailor-made for each manufacturer: a straight-forward route to incorporating nanomaterials.

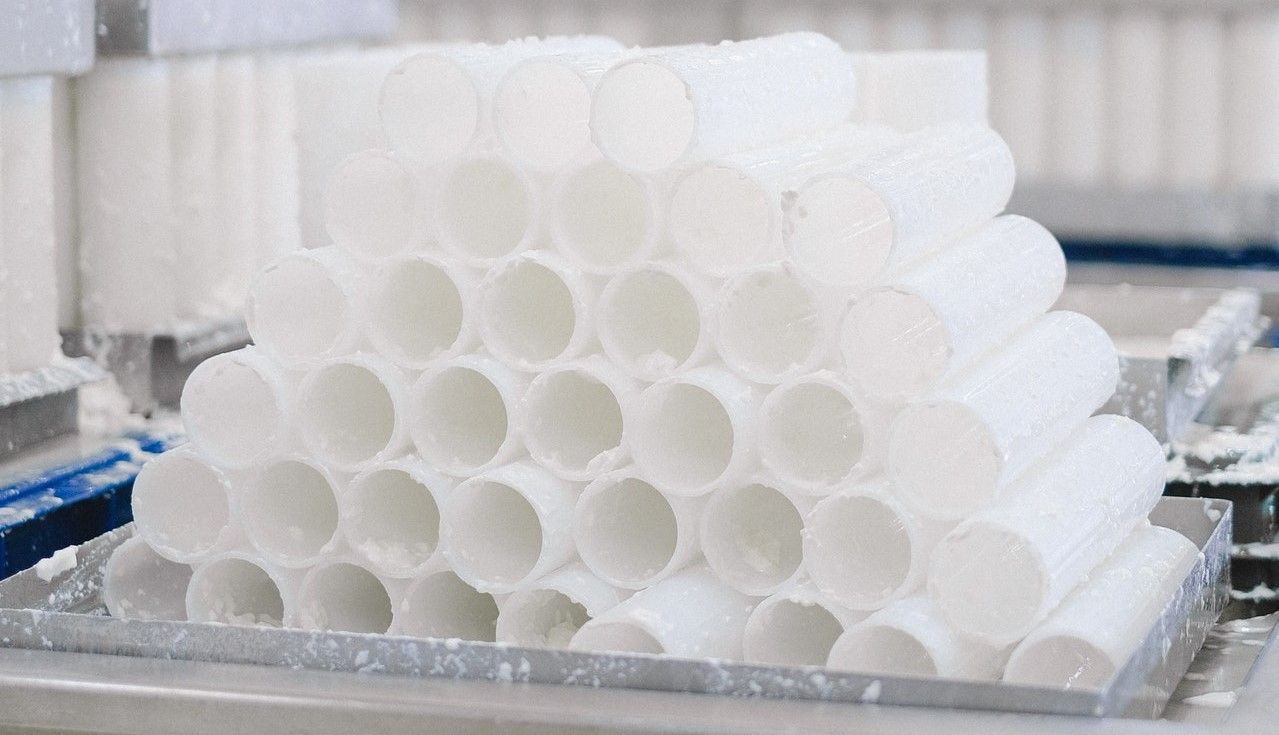

Photo credit: Renata L from Pixabay, Michal Jarmalouk, Anna Shevets from Pexels, Freepik, & NANO CHEMI GROUP