Across many industries, nanotechnology is entering production lines as a practical tool for enhancing materials. One area where this shift is especially clear is polyester resins. These resins — including isophthalic grades — form the backbone of many high-performance products, from industrial floors to protective coatings, composites, and printing rollers.

Conventional polyester resins deliver good hardness, chemical resistance, and cost efficiency. But they also carry limitations, such as brittleness, thermal instability, and electrical insulation, all of which restrict their functionality in demanding applications.

Yet through the addition of nanoscale fillers, these resins can gain higher conductivity, improved toughness, or long-term durability under thermal and UV stress, with numerous academic and industrial studies illustrating just how powerfully nanotechnology can alter their performance.

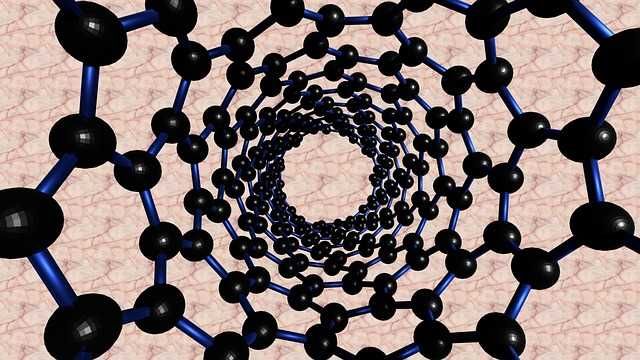

These nanoadditives for polymers include:

· Graphene oxide and nanosilica: According to a study published in DOAJ, incorporating just 0.3 wt% of graphene oxide combined with nanosilica into isophthalic polyester resin led to a 59 % increase in tensile strength and an 82 % increase in flexural strength. Beyond mechanical performance, this formulation also reduced flammability, showing that functional nanofillers can contribute to both safety and strength.

· Halloysite nanoclay: Research reported in the IJSRSET journal and reinforced by a Springer review demonstrated how halloysite nanoclay can significantly improve the thermal stability of polyester resins. The nanomaterial researchers finding that the presence of tubular nanostructures raised degradation temperatures and slowed the rate of weight loss, making the material more resistant to long-term thermal exposure. Specifically, they report that, “The thermal property assessments, particularly the thermogravimetric analysis, [conducted on polyester/NHTs nanocomposite samples] revealed that the samples containing nanofillers exhibited superior heat resistance, with an optimal enhancement observed at 6–8% nanofiller loading, compared to unfilled polyester and halloysite/polyester matrix composites.”

· Cellulose nanocrystals (CNCs): A 2020 study has found remarkable performance gains are possible through the inclusion of bio-based nanomaterials into polyester resins. A study published in the journal Polymers, noting that, “the addition of only 2 wt% CNC increased the nanocomposite flexural strength by 159%, the ductility by 500% and the toughness by 1420%.”

· Oxide nanoparticles (TiO₂ and silica–titania hybrids): Findings published in SAGE Journals show that oxide nanoparticles can significantly alter the dielectric behaviour of unsaturated polyester composites, while also improving their thermal resistance.

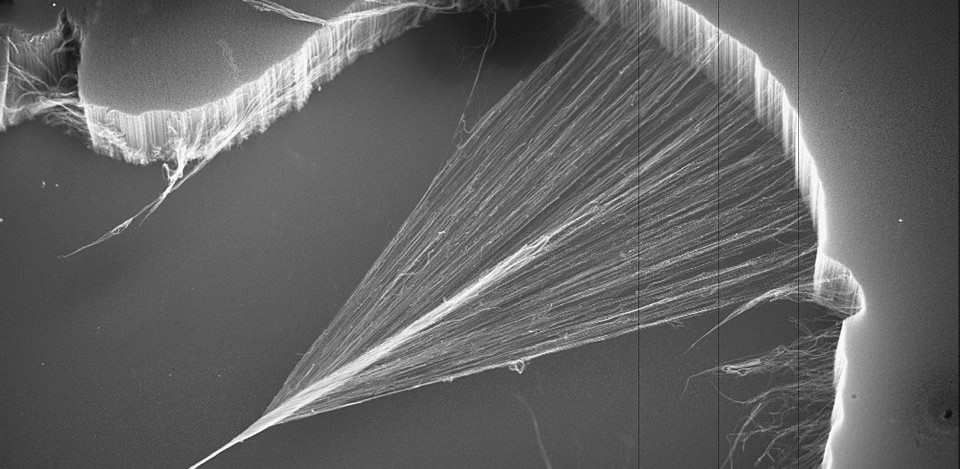

· Carbon nanotubes (CNTs): Research published in MDPI’s journal Nanomaterials found that even very low concentrations of CNTs enhance the durability of polyester systems. Benefits included reduced water uptake, improved UV resistance, higher glass transition temperature (Tg), and greater surface hardness. Such improvements make CNTs particularly attractive for outdoor coatings, flooring, and composites exposed to harsh conditions.

What is striking is that such improvements come from such low nanofiller loadings. This means that compared with conventional fillers, like carbon black or metal fibres, nanomaterials can deliver performance gains without compromising colour, gloss, or processability.

Nanomaterial Benefits for Industry

For manufacturers of ASD and ESD flooring systems, these advances translate into real opportunities, for example, by making it possible to achieve stable, long-lasting conductivity without the need for heavy filler loadings. In the paints and coatings sector, nanomodified polyesters can deliver conductive, wear-resistant finishes with improved UV stability and enhanced fire resistance. While fibreglass and carbon composites also benefit from nanofillers through increased interlaminar shear strength, boosting damage tolerance, and even enabling electromagnetic shielding or lightning protection (often in demand for aerospace and automotive applications).

Even in the production of printing rollers, nanotechnology-enhanced resins provide improved surface conductivity, greater wear resistance, and more consistent ink-transfer uniformity, all while reducing dependence on high-carbon black formulations.

For manufacturers seeking to capture these benefits, turning academic findings into production-ready solutions is the real challenge. To meet this need, the Prague-based business NANO CHEMI GROUP has developed an off-the-shelf solution suitable for inclusion in current polyester production processes.

Supplied as a paste, NANO AC PES-17 is a polyester resin-based concentrate that can boost conductivity in an ESD floor, improve abrasion resistance in a coating, strengthen a composite laminate, or enhance the durability and efficiency of printing rollers.

For manufacturers, these developments in nanomodified polyester resins are more than just a technical breakthrough — they represent a new market dynamic. Demand is shifting toward materials that combine durability, safety, and multifunctional performance without major cost increases or processing changes.

With products like NANO AC PES-17, the barrier between laboratory research and industrial application is narrowing. Rather than competing solely on price, businesses can leverage nanotechnology to offer end-users tangible performance benefits.

From reduced maintenance costs to extended product lifetimes, nanotechnology continues to enter mainstream industrial chemistry by providing manufacturers with both a technological and commercial advantage.

Photo credit: NANO CHEMI GROUP, Dean Simone from Pixabay, Wikimedia, & Sonnysixteen on Unsplash