Concrete remains the backbone of global infrastructure, yet it faces increasing scrutiny over durability, lifecycle costs, and environmental impact. Recent research is now offering a compelling route towards solving all three of these issues with the intelligent application of nano-titanium dioxide.

The news comes from a newly published peer-reviewed study in the journal Nature, which demonstrates that carefully dosed nano-titanium dioxide (nano-TiO2) can substantially enhance concrete performance. Significantly, the study also analysed raw material costs and calculated that the inclusion of the nanomaterial feedstock is economically viable and an expense which more than paid for itself over a structure’s lifetime.

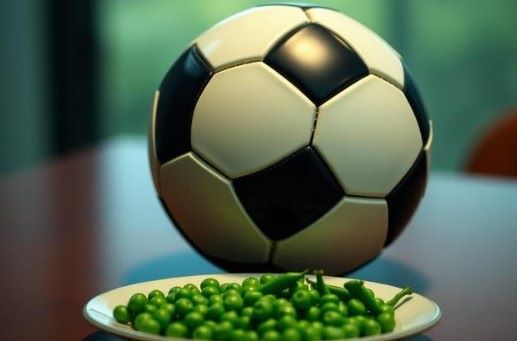

Nano-TiO2 consists of tiny particles of titanium dioxide, in this study each nanoparticle was roughly the size of a large protein molecule. Or to put this another way, if a red blood cell was the size of a football, then the titanium dioxide nanoparticles used in the concrete would be the size of peas.

At this size, nanoparticles have an exceptionally high surface area to volume ratio and phenomenal reactivity. Understanding this, the study found that when introduced into cement mixtures the particles could modify the hydration process. Acting as nucleation sites, the nanomaterials accelerate the formation of calcium-silicate-hydrate gel and refine the internal pore structure of the hardened concrete. The result is a denser, more homogeneous matrix with fewer pathways for water and aggressive chemicals.

Related articles: Improving EPDM Compounds with Nanomaterial Concentrates and Nanotechnology Powers Next Generation Tyres

Mechanical testing confirms the impact that incorporating nano-TiO2 can achieve by producing concrete with markedly higher compressive, tensile, and flexural strength compared with conventional M40 concrete. At 28 days, strength gains approached 30 percent, while long-term curing produced compressive strengths exceeding 75 MPa. From a commercial perspective, this opens the door to either higher-performance structural applications or lower input costs as the quantity of cement can be reduced without sacrificing strength.

Microstructural analysis explains why these gains persist over time, with electron microscopy showing that nano-TiO2 fills micro-voids and strengthens the interfacial transition zone between cement paste and aggregate. This improved bonding translates directly into better crack resistance and load transfer, both critical factors in buildings and bridges exposed to fatigue and shifting loads.

But it is in the characteristic of durability where the breakthrough becomes particularly attractive for the construction industry, as the research demonstrates that nano-TiO2 concrete has enhanced resistance to acidic environments, chloride ingress, and freeze–thaw cycles. Significantly, the lower permeability and higher surface resistivity was found to reduce the risk of steel reinforcement corrosion, one of the most costly failure mechanisms in construction. These improvements directly support longer service life and lower maintenance expenditure, particularly in coastal, industrial, or cold-climate regions.

Moreover, nano-TiO2-modified concrete also retained or even improved strength after exposure to moderately elevated temperatures, suggesting benefits for fire resistance and thermal cycling. While extreme temperatures still degrade performance, the material showed some resilience to common fire-exposure ranges, adding another layer of risk mitigation.

Unfortunately, from a production standpoint, the study also highlights a familiar challenge: reduced workability as nano-TiO2 content increases. However, this is a manageable issue for ready-mix producers through dosage optimisation and the use of modern superplasticisers. Importantly, the research identified that around one percent nano-TiO2 by cement weight as a practical balance point where performance gains are substantial without excessive cost or handling complexity.

The economic analysis is especially relevant, as it dispels the common fear that adding nanomaterials to a product makes it more expensive. Similar to the inclusion of nanotechnology in polymers, resins, and other composite materials, lifecycle modelling shows that while nano-TiO₂ in concrete increases initial material costs, the improved durability and delayed repair cycles more than compensate over time. This positions nano-TiO₂ not as a premium additive but as a smart investment.

As regulatory pressure and client expectations continue to rise, additives that deliver measurable performance and economic benefits will increasingly define competitive advantage.

As the researchers themselves state, the study’s results “underscore the potential of nano-TiO2 as a transformative nanomaterial in concrete technology, improving strength, durability, and resistance to aggressive environments while optimizing microstructural properties.”

For raw material suppliers, nano-TiO2 represents a clear value proposition in strength enhancement, durability improvement, and lifecycle cost reduction. Another example of how nanotechnology can move from academic innovation to industrial advantage.

Photo credit: Gencraft, Shiola Odan on Unsplash, Wes Hicks, & Freepik