Nanotechnology continues to transform the world of advanced materials, and nowhere is this more evident than in the integration of nanotechnology into manufacturing.

This was highlighted in a recent review of how polymer-coated nanosized particles with inorganic cores are impacting industrial feedstocks. Central to the study was the variety of products being enhanced across multiple fields — from flooring systems to electronics, to industrial coatings, biomedicine, and even everyday plastics, like polycarbonate.

For manufacturers, understanding the fundamentals and applications of these hybrid raw materials is essential. Not only do they represent cutting-edge science, but they also point toward practical innovations in polymers, coatings, and resins that are reshaping industrial products and being used to gain a competitive advantage.

What are Polymer-Coated Nanoparticles?

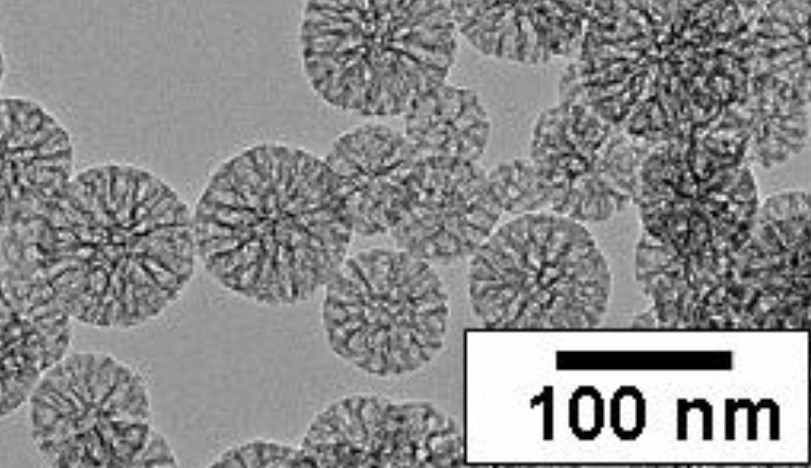

In simple terms, a polymer-coated nanoparticle consists of a metal or metal-oxide core enveloped by a carefully tailored polymer shell. This combination brings together the unique electrical, magnetic, mechanical, or chemical properties of inorganic nanomaterials with the flexibility and functionality of polymers.

According to the study, which was published in the November 2025 edition of the journal Nanomaterials, polymer coatings enhance the “stability, biocompatibility, and functional versatility” of the nanoparticles, making them far more effective in real-world applications.

Specifically, the study, compiled by nanomaterial researchers from the University of Texas, explains how the effect of polymer-coated nanoparticles is “based on their inorganic core materials, including gold, silver, copper, platinum, palladium, iron oxide, titanium oxide, zinc oxide, and aluminum oxide. [Where] Each of these materials exhibits distinct properties, which are further enhanced by polymer coatings.”

Adding that, alongside their application in conventional manufacturing, they are providing solutions in niche sectors such as “biosensing, photothermal therapy, targeted drug delivery, energy storage, environmental remediation, MRI, electronics, and antimicrobial treatments.”

How Are These Nanostructures Made?

Synthesizing polymer-coated nanoparticles requires nuanced control over surface chemistry, where nanotechnology specialists can employ several strategies that affect how the polymer binds and how the final particles behave. These include:

· Grafting approaches to enable strong covalent attachment of polymer chains to cores.

· In situ polymerization to allow polymer formation directly at the nanoparticle surface.

· Layer-by-layer assembly to build multi-layered shells with tuneable properties.

Each of these methods governs not only the size and shape of the raw material but also its surface functionality—both essential factors for practical integration into commercial polymers and coatings.

Often referred to as nano effects, compared with conventional fillers or additives, polymer-coated nanoparticles can improve mechanical properties, thermal-conductivity, optical behaviour, electrical-conductivity, and resistance to UV-light, harsh chemicals, and general wear or degradation.

Although nanotechnology is influencing a broad range of manufacturing, several areas stand out for their relevance to polymers and coatings:

Advanced Coatings

By integrating polymer-coated metal oxides like titanium dioxide and zinc oxide, coatings can achieve improved UV shielding, corrosion resistance, and self-cleaning behaviour.

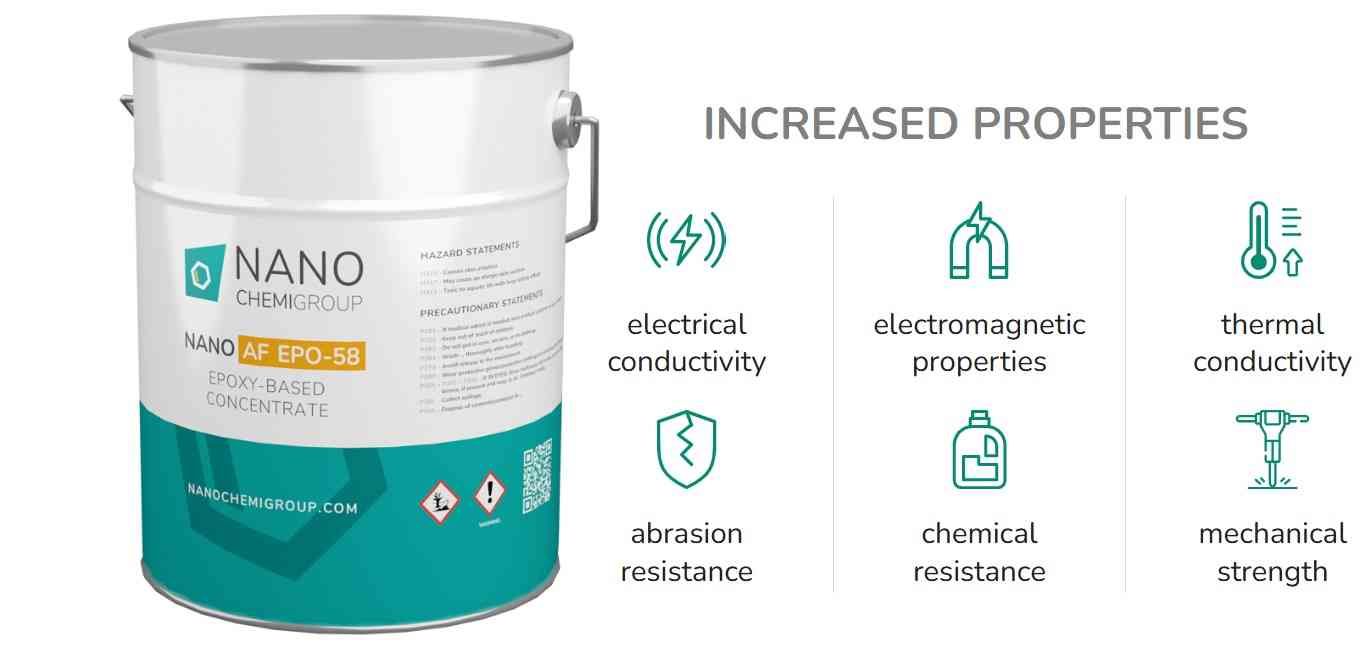

For example, the nanomaterial specialists at NANO CHEMI GROUP have designed carbon-nanomaterial-enhanced polymer concentrates, such as NANO AF EPO-58 and NANO AC PES-17, to improve the functional performance of epoxy resin and polyester resins respectively. Specifically, these nanomaterial additives boost mechanical strength, electrical and thermal conductivity, and durability when incorporated into industrial floorings and composites.

Electronics and Energy

Nanoparticles engineered with conductive polymer shells show promise in printed electronics and flexible devices. Their surface modifications enhance charge transfer while maintaining mechanical robustness.

When formed into industrial additives, these carbon nanomaterial-based concentrates can enhance electrical properties in polymeric composites, a key feature exploited in flexible sensors or environmental monitoring materials where conductive pathways and signal responsiveness are needed.

Biomedical and Environmental Technologies

Although outside traditional polymer processing, polymer-coated nanoparticles also show potential in sensors, antimicrobial surfaces, and environmental remediation, highlighting the versatility of polymer-inorganic nanosystems.

For example, NANO CHEMI GROUP (who sponsor this webpage) offers nanostructured additives such as NANO AB PA6, a colloidal silver nanoparticle solution with particles up to 40 nm, which can be incorporated into polymers to impart antimicrobial functionality useful in medical device housings or hygienic surfaces.

These types of nanoscale polymer-inorganic composites underline how tailored nanoadditives can open up applications for conventional products to be advanced with functionality and unique selling points.

They indicate how polymer-coated nanoparticles represent a significant leap in material design, blending nanoscale function with polymer versatility. As the academic review underscores, these hybrid materials hold promise for everything from the stronger, smarter coatings of tomorrow to next-generation electronic and biomedical technologies.

But today, they offer a practical way for manufacturers to create product value without lowering prices.

To find out more about how nanotechnology can improve manufactured products, visit NANO CHEMI GROUP or contact info@nanochemigroup.cz.

Photo credit: Freepik, NANO CHEMI GROUP, Wikimedia, NANO CHEMI GROUP, & Gencraft