PVC is one of the most industrious polymers ever commercialised. From pipes and window profiles to cables, flooring, and films, it turns up everywhere — largely because it is affordable, durable, and easy to process at scale.

Yet anyone who actually works with PVC knows the trade-offs. Heat, UV exposure, and long-term mechanical stress still define where PVC can compete — and where it starts to fall short.

This is where nanotechnology—the control of materials at the very, very small—can help. By adding carefully selected nanomaterials, manufacturers can push PVC well beyond its traditional performance envelope — often without changing existing processing equipment.

Why Standard PVC Has Limits

Unmodified PVC performs well in many environments, but it struggles when conditions become demanding. Thermal degradation, brittleness over time, colour changes under UV exposure, and limited mechanical reinforcement all create trade-offs between cost and durability. Traditionally, these issues are addressed with stabilisers, fillers, and plasticisers — effective solutions, but not always enough.

Nanotechnology takes a different approach by improving how a material behaves at a molecular level.

What Nanomaterials Actually Do Inside PVC

Because of their extremely small size and large surface area, even low loadings of nanomaterials can influence how polymer chains move, how heat travels through a material, and how stress is distributed.

In practical terms, nano-enhanced PVC can offer:

· higher thermal stability without heavy stabiliser packages.

· improved mechanical strength and impact resistance.

· better UV resistance and slower ageing.

· enhanced barrier, dielectric, or surface properties.

All of this can be achieved while keeping formulations lean and processing familiar.

Common Nanomaterials Used in PVC

Different nanomaterials deliver different benefits, depending on the application and formulation strategy.

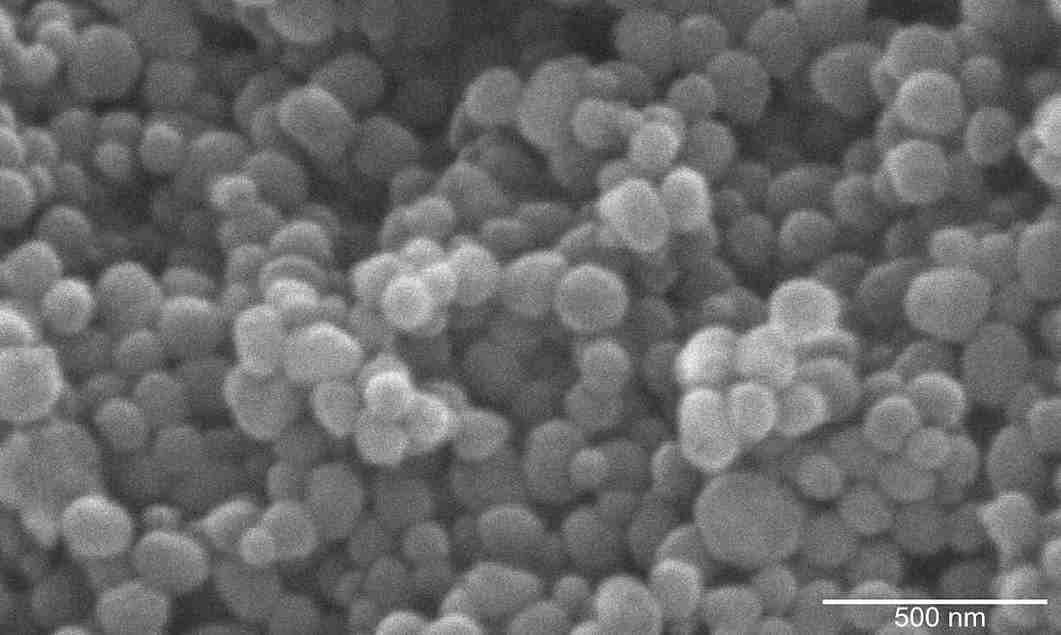

Metal oxide nanoparticles such as zinc oxide or aluminium oxide are often used to improve heat resistance, UV stability, and dielectric behaviour. Silica nanoparticles can refine surface properties, improve dispersion of other additives, and contribute to mechanical reinforcement. Nanoclays, when properly exfoliated, improve stiffness, barrier performance, and dimensional stability. Whereas carbon-based nanomaterials, including graphene derivatives, are used where conductivity or advanced reinforcement is required.

Achieving these enhancements no longer requires a large R&D budget to support hours of laboratory experiments and testing. This is because the science of nano-enhanced PVC is well-known and is already delivering clear advantages in real markets.

For example, in construction products, nanotechnology is providing improved weathering resistance and long-term mechanical stability—translating directly into longer service life and fewer warranty issues. In cables and electrical applications, nanomaterials are adding better thermal and dielectric performance to improve safety margins. While for membranes, films, and industrial components, nanoscale modification can unlock higher performance without switching to more expensive polymers.

Related articles: Manufacturing Redefined with Polymer-Coated Nanoparticles and Improving EPDM Compounds with Nanomaterial Concentrates

Furthermore, as the addition of nanomaterials can mean a reduction in the use of conventional polymers and fillers, manufacturers of PVC which choose to benefit from nanotechnology often gain a better price-performance ratio. Sometimes raw material costs can even be reduced.

PVC, Reinforced for the Next Decade

Nanotechnology offers a practical route to extend PVC’s relevance, improve margins and open new application areas without reinventing production lines. In this way, PVC is not being replaced — it is being upgraded.

The trick to gaining these commercial advantages is in knowing someone who knows how.

At NANO CHEMI GROUP, nanotechnology is approached with one goal in mind: measurable performance gains that make business sense. Based in Prague, the company (which sponsors this page) works closely with polymer producers to improve PVC formulations using proven, off-the-shelf nanomaterials or fully tailor-made solutions for specific applications. To find out how NANO CHEMI GROUP’s products can enhance your PVC compounds, contact info@nanochemigroup.cz or visit NANO CHEMI GROUP. Because nano-enhanced PVC is not a future concept — it is already a cost-saving technology and a provider of higher performance.