Why is nanotechnology suddenly so important? How can a material that is so small (about half the size of a red blood cell) be so influential? And how can a nanoparticle which measures only a few nanometres wide (1 mm = 1,000,000 nm) have any impact on manufacturing and bulk raw material supplies?

To understand the power of nanomaterials, one needs to understand how materials work at the very small scale.

For example, if you look at a sandy beach from a long way off, the sand looks yellow. It is only when you look closer that you can see that the individual grains of sand are in fact all sorts of different colours mixed together.

Nanotechnology scientists have found that materials work in the same way.

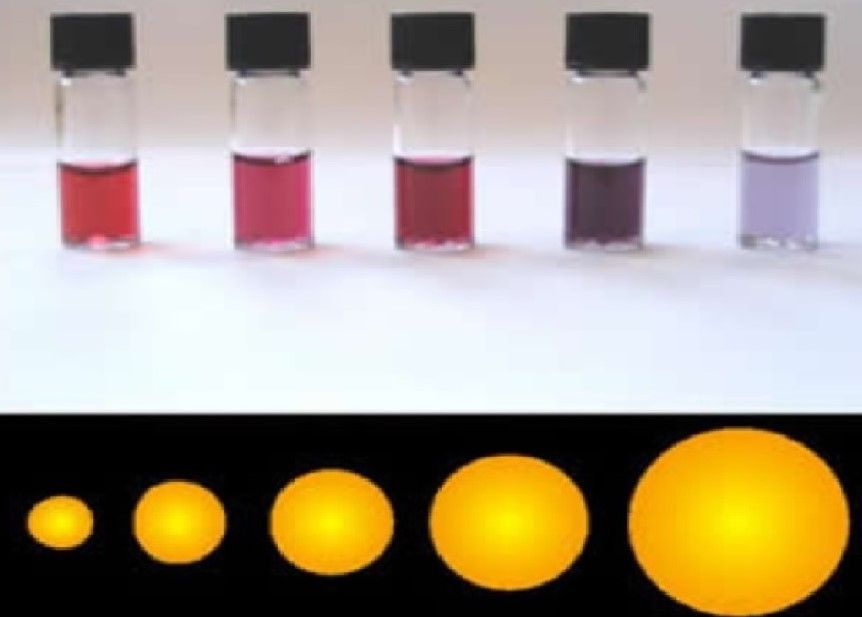

In its bulk form, gold is the colour gold, but when examined at the nanoscale it can be blue, red, or purple depending on the size of the particles and the distance between them.

In the macroworld, gold reflects light, but at the nanoscale, the electron cloud at the surface of a gold nanoparticle resonates with different wavelengths of light depending upon their frequency. The size of the nanoparticle affects the electron cloud and dictates which wavelength of light will be absorbed.

A nanoparticle of gold about 90 nm in size absorbs reds and yellows from the colour spectrum, making the nanoparticle appear blue or green. However, a nanoparticle of gold measuring only 30 nm, will absorb blues and greens, and so will appear red.

In the same way that gold’s colour can change at smaller scales, so too can its other properties.

For example, gold is not typically used as a catalyst in chemical reactions. It is an inert metal that doesn’t react much, so it doesn’t even rust. However, at the nanoscale it works as a catalyst which can, for instance, oxidize carbon monoxide.

But why do particles behave differently at the nanoscale?

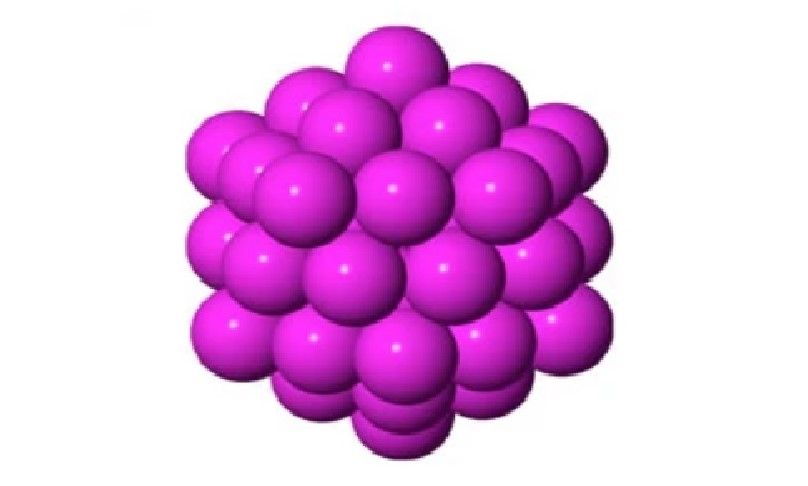

Nanoparticles work differently to bulk materials because of the larger proportion of atoms at their surface.

When in bulk form, each gold atom (except the small percentage of them at the surface) is attached to twelve other gold atoms, while atoms at the surface have six adjacent gold atoms. In a gold nanoparticle a much larger percentage of gold atoms are at the surface.

These exposed atoms are more reactive than those that are surrounded, and this makes nanoparticles of gold more reactive, and better at catalysing reactions.

A single atom has one atom at the surface and zero inside. A ten-atom particle has 9 atoms on the surface and one inside.

Other factors, such as how the electrons interact with each other, also play a key part in how nanoparticles work.

So, the small size of a nanoparticle is not a disadvantage, but in fact gives it the special properties that makes it so useful.

In manufacturing, nanoparticles may contain as many as a few thousand atoms, whereas bulk materials are made up of many billions of atoms.

Ultimately, it means that nanomaterial specialists are able to redesign materials so that they have new properties.

What does this mean for industry and manufacturing?

Manufacturers are now able to use nanomaterials to give their products new properties and selling points.

A polymer can now be made to be a better conductor of electricity. Anti-microbial properties or electro-magnetism can also be applied. Materials can be given extra strength, chemical resistance, or ductility.

Furthermore, because their small size makes them so efficient, just a tiny amount of nanomaterials can provide the desired properties without any unwanted change to the original material.

This means that a coating can be given improved scratch-resistance or protection against fading without impacting the desired colour. A plastic can be made stronger yet remain flexible. A rubber compound can be made lighter yet also more durable. Alternatively, a nanomaterial can replace a bulk material, potentially reducing raw material costs.

Nanotechnology has suddenly become important because material researchers have only just begun to tap the enormous range of possibilities that it can provide. Meanwhile, manufacturers are only now beginning to realise how nanomaterials can have such a positive impact on their products.

To find out more about how nanomaterials are influencing manufacturing contact by calling +420 233 371 850, emailing info@nanochemigroup.cz or by visiting NANO CHEMI GROUP.

Photo credit: Siim Sepp (Sandatlas), nature, Aleksandar Kondinski, Pashminu Mansukhani, andreas160578, & motionstock