Graphene, a material that measures just a single atom thick yet remains one of the strongest materials on Earth, has again astounded the scientific community by proving its strength even under repeated stress.

The discovery was made at the University of Toronto where nanomaterial researchers analysed samples of graphene with repeated impact tests. From the results they concluded that the material could withstand more than a billion cycles of high stress before it breaks.

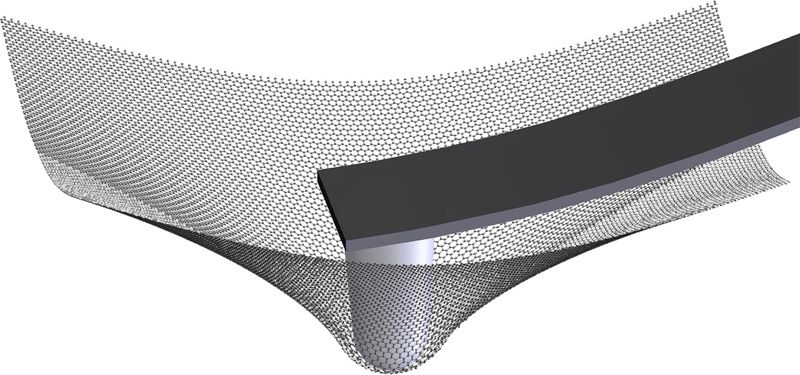

While the researchers are still unsure why graphene is so strong, current theories link its durability to its structure of interlocking hexagonal rings which consists of a single carbon atom at each junction connecting it to the next ring. This powerful design gives the 2D material an intrinsic strength of more than 100 gigapascals, one of the highest ever recorded for any substance. It is a property that keeps this nanomaterial in high demand.

However, up until now, little had been known about how graphene is affected by repetitive stress.

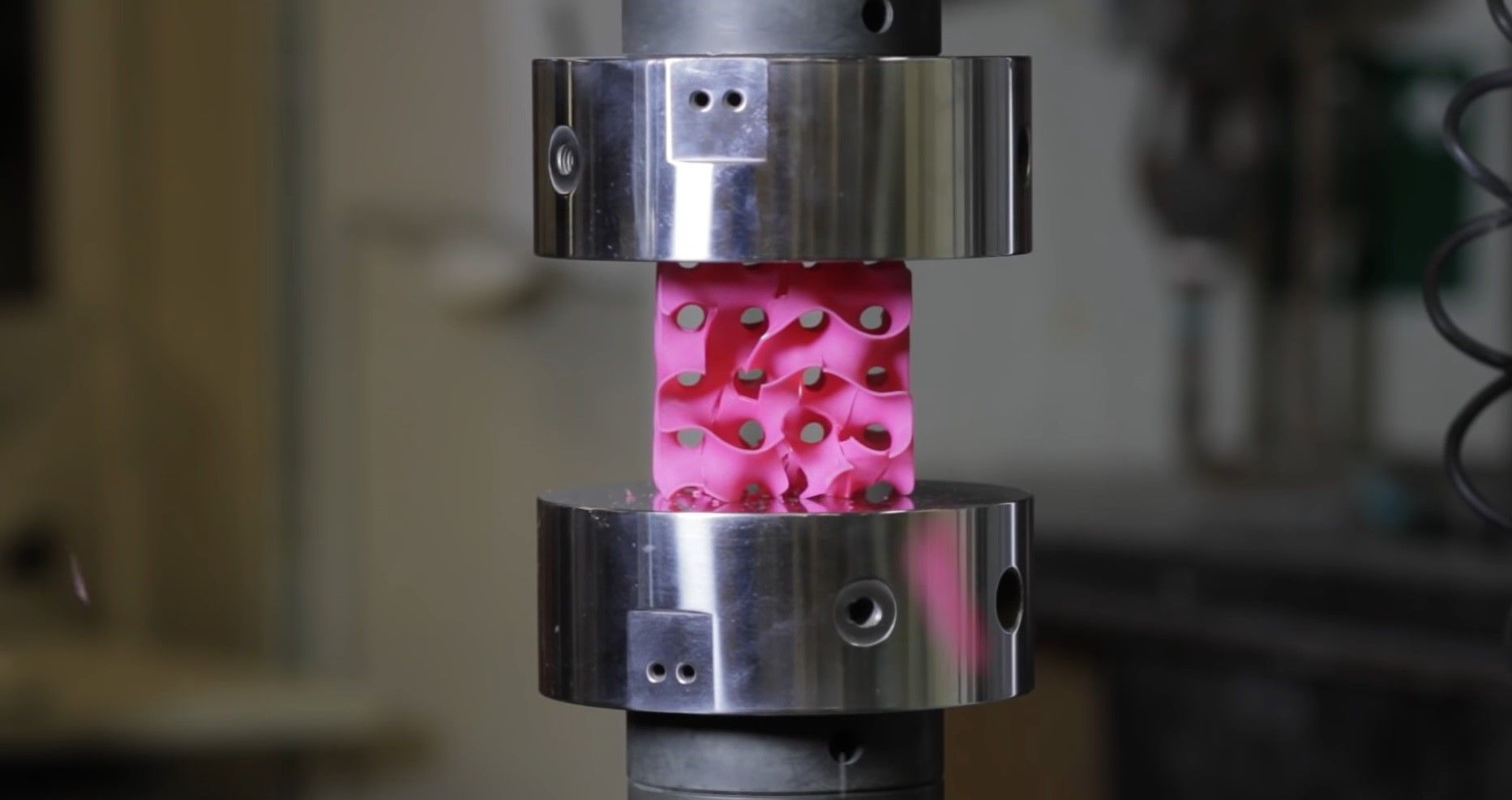

This is significant, as most materials fail not because the load exceeds their maximum strength but through repeated stresses and impacts that gradually weaken the substance over time. The weakening is caused by microscopic dislocations and fractures, a process known by engineers as fatigue.

“To understand fatigue,” says Professor Tobin Filleter, one of the study’s senior authors, “imagine bending a metal spoon. The first time you bend it, it just deforms. But if you keep working it back and forth, eventually it's going to break in two.”

The research was based on both physical testing and computer simulations.

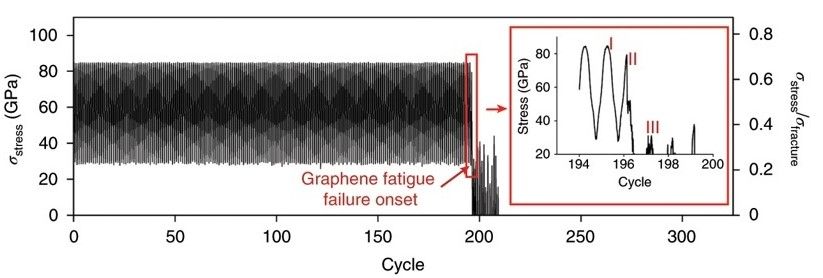

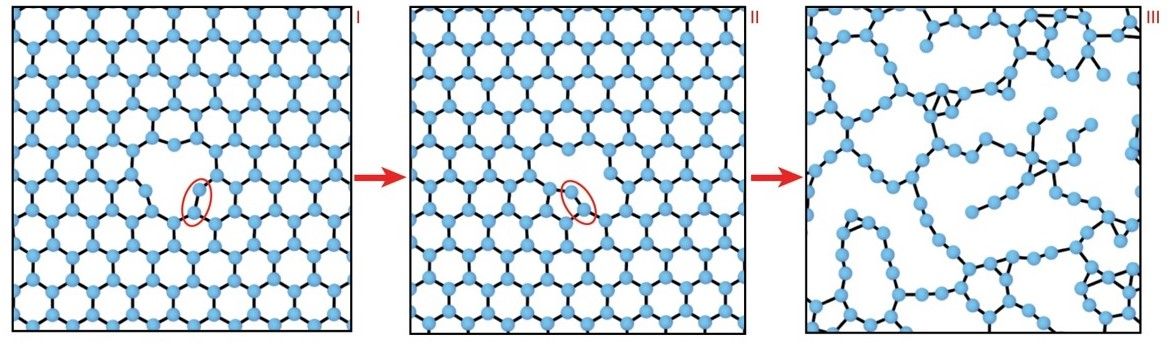

“In our atomistic simulations, we found that cyclic loading can lead to irreversible bond reconfigurations in the graphene lattice, causing catastrophic failure on subsequent loading,” says Associate Professor Chandra Veer Singh, who led the modelling side of the study with postdoctoral fellow Sankha Mukherjee. “This is unusual behaviour in that while the bonds change, there are no obvious cracks or dislocations, which would usually form in metals, until the moment of failure.”

While these computer models highlighted that something extraordinary was happening to graphene under stress, it took physical experimentation to conclude just how durable nanomaterial sheeting can be.

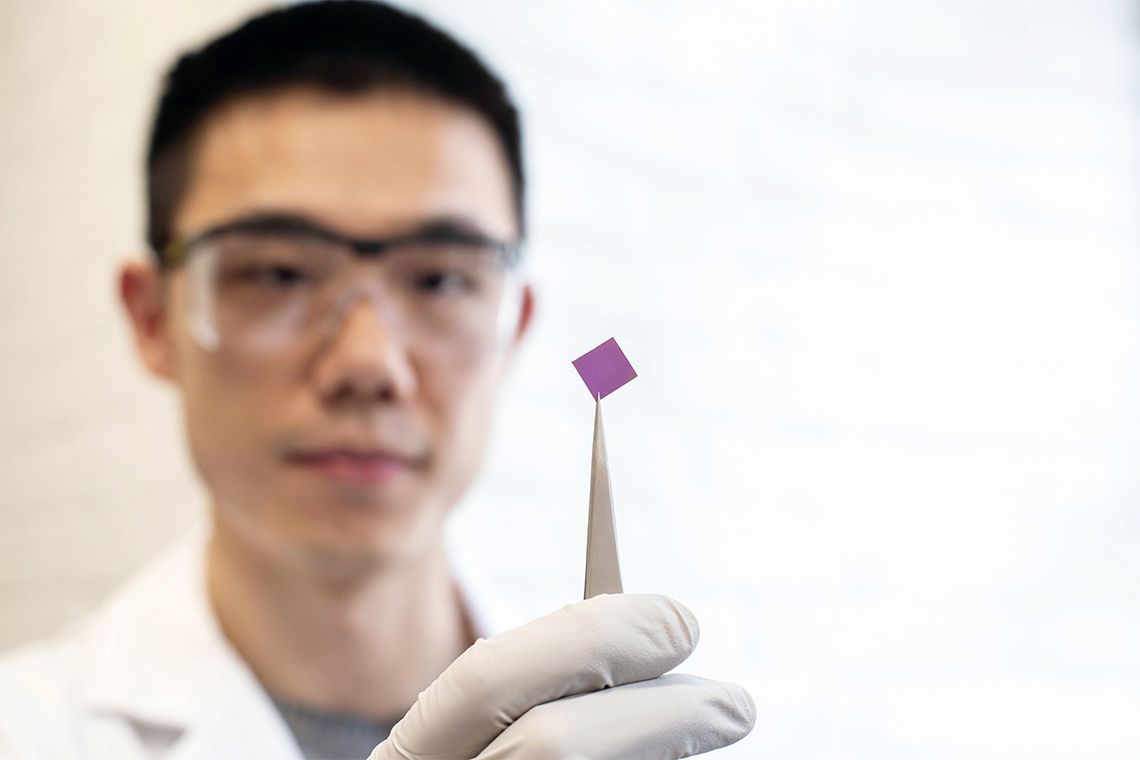

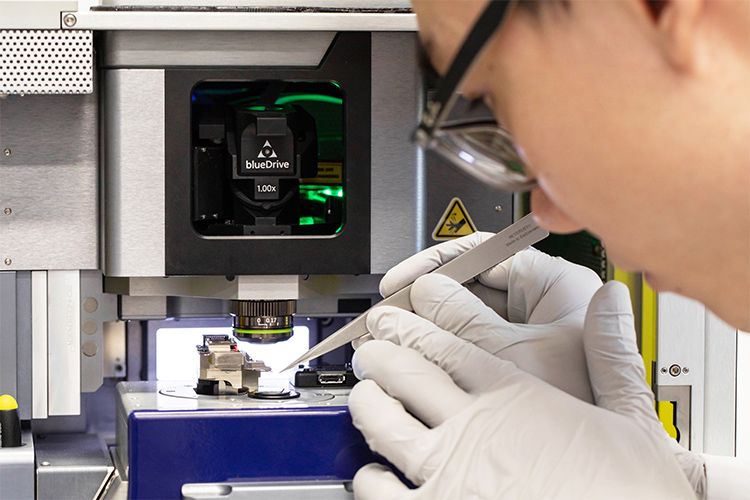

As the university website explains, “The design consisted of a silicon chip etched with half a million tiny holes only a few micrometres in diameter. The graphene sheet was stretched over these holes, like the head of a tiny drum.” Then, “Using an atomic force microscope, Cui [Ph.D. candidate Teng Cui] then lowered a diamond-tipped probe into the hole to push on the graphene sheet, applying anywhere from 20 to 85 percent of the force that he knew would break the material.”

“We ran the cycles at a rate of 100,000 times per second,” says Cui who constructed and carried out the physical tests. “Even at 70 percent of the maximum stress, the graphene didn't break for more than three hours, which works out to over a billion cycles. At lower stress levels, some of our trials ran for more than 17 hours.”

Even through such rigorous stress testing the graphene either remained wholly intact, without fissures or evidence of fatigue, or it broke. There was no evidence that repeated stress had compromised the nanomaterials structure.

“Unlike metals, there is no progressive damage during fatigue loading of graphene,” says fellow researcher and Engineering Professor Yu Sun. “Its failure is global and catastrophic, confirming simulation results.”

To make a comparison, the team also tested graphene oxide, which is a material with similar properties to graphene, with small groups of atoms such as hydrogen and oxygen bonded to both the top and bottom of the nanomaterial sheet.

These tests found that although the graphene oxide is also near-atomically thin, the material reacted to stress impacts in a way more like conventional substances. Cracks appeared in localised areas, which progressed in familiar stages before the structure failed.

Graphene’s resistance to stress is almost unique.

“There are no other materials that have been studied under fatigue conditions that behave the way graphene does,” says Filleter. “We're still working on some new theories to try and understand this.”

Further work is also being done to broaden the range of applications for graphene in manufacturing.

Already the nanoscale sheeting is used in a number of pieces of high-performance sports equipment, such as skis and tennis rackets, however more advanced composites of graphene and polymers have been successfully used in microelectronics as heat sinks, or in sensors and films. The nanomaterial also has uses in batteries, due to its energy storage capabilities, as well as in coatings and durable composites for boat and aeroplane design.

The military also employs graphene for the manufacture of advanced military hardware or for use in satellites.

Larger markets may include building cars with graphene composites, where the material’s extremes of lightweight and strength may combine to make safer, more fuel-efficient vehicles. This makes graphene a more environmentally friendly substance than many conventional raw materials.

Understanding graphene’s reaction to stress will aid further researchers in deploying 2D materials in ever more futuristic composites.

“There have been some studies to suggest that graphene-containing composites offer improved resistance to fatigue, but until now, nobody had measured the fatigue behaviour of the underlying material,” notes Filleter. “Our goal in doing this was to get at that fundamental understanding so that in the future, we'll be able to design composites that work even better.”

“Materials can suffer mechanical fatigue when subjected to cyclic loading at stress levels much lower than the ultimate tensile strength, and understanding this behaviour is critical to evaluating long-term dynamic reliability,” the study, now published in the journal Nature Materials, states. “This study not only provides fundamental insights into the fatigue enhancement behaviour of graphene-embedded nanocomposites, but also serves as a starting point for the dynamic reliability evaluation of other 2D materials.”

Photo credit: UniversityofToronto, Theforteanslip, CNN, Innovator, UniversityofToronto, & Phys